We are proud to announce a new addition to our ever-expanding gas sensing range; with the release of our SF6 gas detection solutions. Our SF6 gas detection equipment utilises world-leading, interference-free, non-dispersive infrared technology, both in a diffusion-based, non-ATEX detector and in our industry-leading 750 samplers. Our SF6 gas detection solutions provide clients with an industry-leading, cost-effective, and reliable solution for continuous SF6 monitoring. Plus, with a 5-year lifetime, long term upkeep costs are reduced.

What is SF6 Gas?

Sulphur Hexafluoride or SF6 is a colourless, odourless gas, which is heavier than air and has asphyxiant properties. It is classed as a toxic gas under UK EH40 regulations and OSHA, with exposure levels of 1000ppm/8hrs and 1250ppm/15mins. SF6 is also one of the world’s most potent greenhouse gases, with a global warming potential of 23,900 times that of CO2. This means that SF6 is now closely monitored by the F-Gas directive, which bans, or controls, the emission of particular greenhouse gases. Due to its high global warming potential, and toxicity of its bi-products (mainly disulphur decafluoride (S2F10)), we have developed an IR sensor, so that you can detect SF6 leaks at low-level parts per million. Thus, detecting leaks before it damages the environment, and before it can accumulate to asphyxiant and toxic levels.

Where is SF6 Used?

Due to its high global warming potential, there is a limited number of applications where SF6 is utilised. Below are some of its main applications:

- Insulating gas for high voltage switch gears, circuit breakers, and electrical equipment. This is because, under pressure, SF6 has a much higher dielectric strength than air or nitrogen. This means that gas-insulated switchgears can be placed indoors and can be significantly smaller in size compared to air-insulated switchgears. However, it is important to monitor for low-level SF6 leaks both due to its global warming effects but also ensuring there is no risk of damage to the switch gears, as these are normally unmanned areas. (see below IGD’s solution for remote sites). [Check this useful whitepaper here on Sf6 as an insulating gas.]

- Tracer gas for fume cupboard integrity testing. It is routinely used as part of the final test during fume cupboard integrity testing.The gas is used in the final stage. It is injected inside the fume cupboard and a range of tests are conducted. An analyser, or detector, is placed outside of the cupboard to ensure that the SF6 is contained within the fume cupboard.

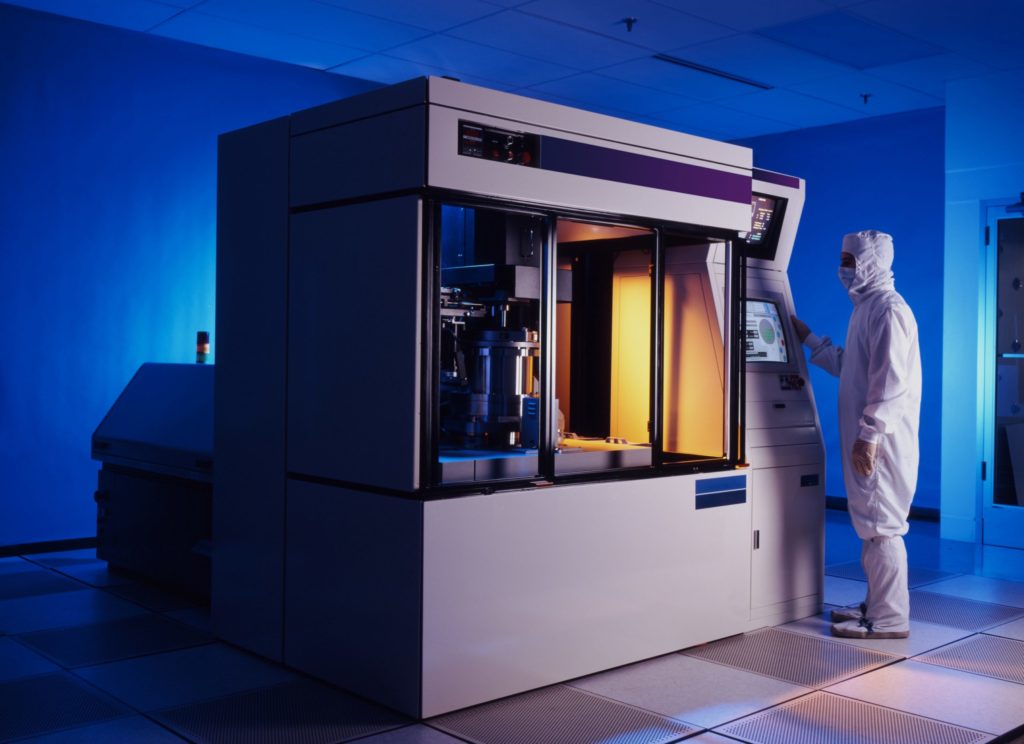

- Semiconductor industry. Sulphur Hexafluoride is used as a plasma in the semiconductor/wafer fab industry, for use as an etchant. The SF6 will break down in the plasma to form sulphur and fluorine. The fluorine plasma is the main component that performs the etching process. Since it is listed as a toxic gas under COSHH regulations, it is imperative that companies using SF6, as part of the process, monitor for any leaks or accidental release.

New SF6 Gas Detection Solutions

Our new line of IR SF6 gas leak detectors, provides a unique solution for continuous SF6 monitoring. The detector uses ground-breaking NDIR sensors coupled with our industry-leading addressable communication technology. This provides the client with all the benefits of 2-Wire Addressable including installation cost-saving, but also with distributed control and a wide range of reporting features. The new NDIR sensor also provides unparalleled stable detection even at low ranges of 0-1000ppm.

Our IR SF6 gas detector provides reliable detection with no interference from temperature, humidity or other gases. Our sensor features an above industry standard operational life of 5 years. Our 2-Wire Addressable gas detection technology also enables users to have remote alarms utilising either GSM modules for texts and email alerts or remote accesses via the cloud. This is especially useful for remote installations, such as switchgear premises, in alerting offsite personnel of leaks as soon as they happen.

We provide our SF6 gas detectors in two variants depending on the application. The 750-diffusion monitor, which has local I/O capability for controlling other devices and ancillary equipment.

Alternatively, if the environment is particularly demanding, hard to access or is a cleanroom; then our 750 Sampler is the ideal solution. Our 750 sampler allows you to draw a sample from up to 20M away, with near-continuous detection. The 750 Sampler also features virtually no moving parts, utilising our ground-breaking piezo pump technology. Thus, reducing maintenance costs and detector downtime. No matter the application IGD has a solution for your SF6 gas detection requirements.

Contact Us Today

Want to learn more about how we can help with your SF6 gas detection requirements? Or require project support and quotation? Contact us here today or call us on +44 (0)161 483 1415

Subscribe today to our newsletter.