IGD and our distributor in Norway, Vestteknikk, recently tendered and supplied continuous ground gas monitoring equipment to a site in Oslo Norway called Grønmo. The Department of Renovation and Energy at the municipality of Oslo, required a gas detection system that could monitor for hydrogen sulphide, oxygen, and methane gas inside the two buildings on the Grønmo site. This was an international tender that required flexible and cost-effective gas detection equipment with the ability to log alarm data on site. IGD and Vestteknikk won the contract to supply, install, and maintain the ground gas monitoring equipment. Read further to understand more about this application and our solution for ground gas monitoring.

Ground Gas Monitoring Specification:

The municipality of Oslo, Department of Renovation and Energy Recovery is running a depot on the outskirts of the city. The site is named Grønmo. The site activity is based around composting garden waste and where the inhabitants and companies may deliver their waste. The waste is then sorted into containers. Historically the site used to be a domestic waste landfill facility. This means that the site experiences periods of degassing from the ground. A gas treatment system is in place where pipes in the ground deliver collected gas to a generator/combustion engine. Some of this gas is used as a heating source for buildings, but occasionally the gas is flared off. Also, it was highlighted that during maintenance of the generator engine there is a risk of gas leaks occurring.

The Grønmo site has 2 buildings on site – a workshop and resting barracks. Both buildings have through the years experienced gas leaks that have been migrating through from the ground. The primary gases that have leaked through are hydrogen sulphide and methane. Both buildings do have ventilation however the Department of Renovation and Energy Norway conducted a risk assessment and asserted that a continuous ground gas monitoring system must be installed. This was to provide enhanced safety to employees on site and for the gas detection equipment to control the ventilation. This led to a tender where the Department of Renovation and Energy Oslo, asked several suppliers for a gas detection solution. IGD and Vestteknikk won the tender and completed the installation in September 2020.

Installation of Ground Gas Monitoring System:

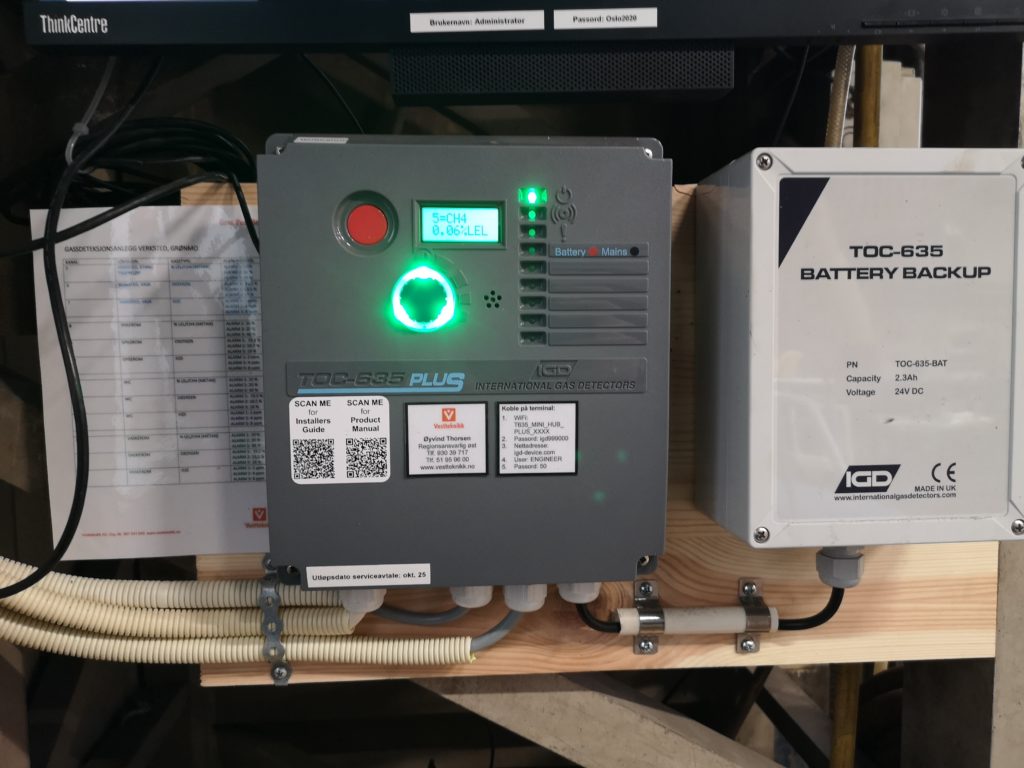

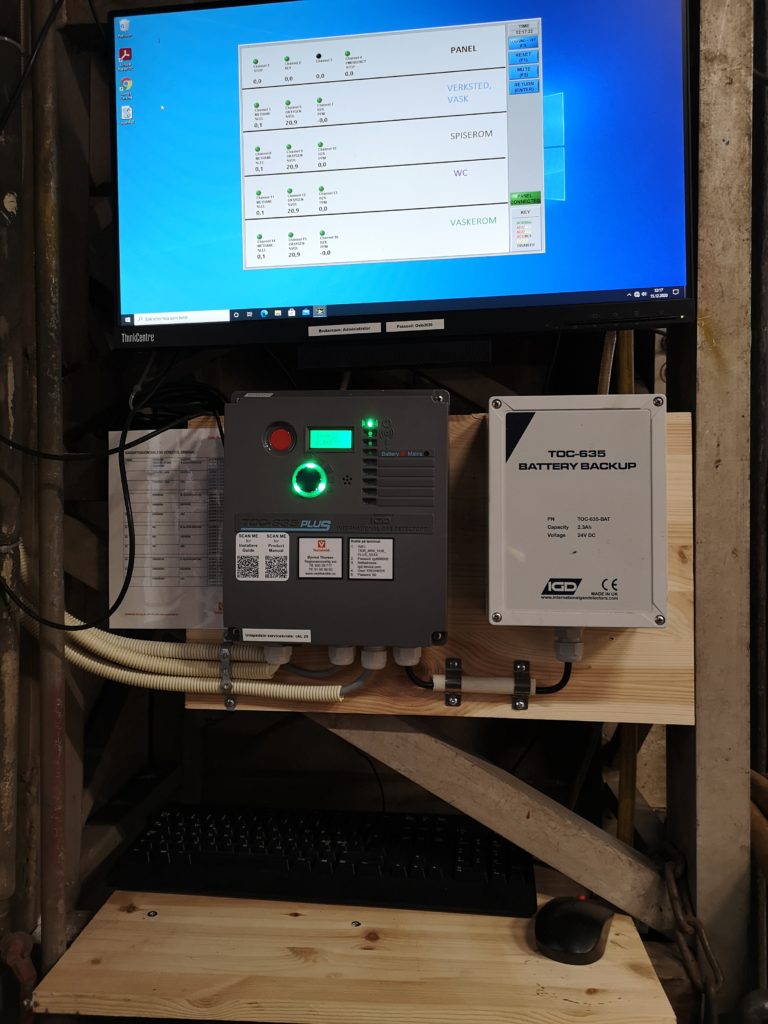

IGD and Vestteknikk provided a quote using our ground-breaking and flexible 2-Wire Addressable gas detection technology. As the site only required two systems with up to 12 detectors in total on each system, our new TOCSIN 635 PLUS gas detection control panel was the ideal solution. The TOCSIN 635 is a cost-effective and flexible solution, to meet the demands of the specification. The TOCSIN 635 PLUS can have up to 32 detectors on a single addressable, 2-Core cable highway (interconnected). Also, the 635 PLUS has onboard relays and a built-in Slam switch. The illuminated jog wheel and the industry first, 1 Click Automatic Alarm and System Setup, was a major benefit for the client.

We supplied our 750 safe area addressable gas detectors for methane (pellistors), oxygen, and hydrogen sulphide. A particular advantage was the use of our long life 5 year+ oxygen and pellistor detectors. Also, our pellistor sensors are the world’s most poison resistant detectors available on the market. This was a major advantage and unique selling point, as it reduces the long-term upkeep cost for the client whilst providing unparalleled detection quality.

TOCSIN 635 Panel Installation

The installation took place during September 2020 which due to our innovative 2-Wire Addressable technology, was a fast and cost-effective installation. The unique automatic system and alarm setup feature on the TOCSIN 635 meant that with one click of a button, the ground gas monitoring system alarm and the system were fully set up automatically. Thus, reducing installation and commissioning time and any possible human errors with setup, which is a drawback of alternative gas detection technologies including dated analogue (4-20mA) systems.

The TOCSIN 635 PLUS gas detection control panel was installed in the workshop area, with a total of 12 detectors (O2, H2S, and Methane). As part of the tender, the site required the alarms and data log to be stored on a local PC. We were able to provide this using our free PC software connected to the TOCSIN 635 PLUS via the onboard RS485 output. This meant that the site HSE personnel were able to view any live alarms remotely via their PC and any previous alarm records and download these to their internal health and safety records. The ability to do this was a major requirement when the tender went live. The TOCSIN 635 PLUS gas detection control panel was also fitted with battery backup in case of any site power failures. A similar installation was provided in the resting barracks, however this time there were only 9 detectors connected to the TOCSIN 635 PLUS gas detection control panel.

The End Result

Oyvind, the lead project engineer at Vesteknikk quoted “This was the first installation in Norway with IGD and we are pleased to inform that the client is very satisfied with the work and the efforts from us. The ease of installation meant we were able to keep within budget and reduced time spent on site. The ability to set the system up via your phone was a major success and was easy to navigate and use the TOCSIN 635 system. The continued support from IGD was incredibly helpful and made our first installation easy. So far, the equipment has proved to be stable and functioning without any operational problems. Vestteknikk is very pleased with the cooperation with Oslo Municipality and especially the staff in place which also seems to be mutual”

Our Sales Director, Colin Peake, also comments on the first installation of IGD’s 2-Wire Addressable technology in Norway – “IGD were very happy to support Øyvind and all the team at Vestteknikk in winning this first project; not just with the product supply but our initial work in providing gas hazard coverage overview for the client to understand their risks and how they could be mitigated.

The IGD 2-Wire Addressable gas detection system appeared perfect for the application; interconnecting gas detection on a single 2-Core, multi drop cable reduced installation costs; local detectors were able to control beacon sounders directly from the detector. This further reduced the cabling requirements and therefore associated costs.

The project was designed quickly and Vestteknikk personnel quickly understood the IGD system enabling them to integrate quickly and already achieve further successes with further projects. Well done to all involved.”

Project Conclusion

The Department of Renovation and Energy at the Municipality of Oslo was impressed with the installation and equipment provided by both IGD and Vesteknikk. Further to this, this was the first installation of our ground-breaking 2-Wire Addressable technology in Norway.

This installation demonstrates the need for more advanced gas detection equipment to meet clients increasingly sophisticated requirements. IGD’s advanced addressable technology easily wins out over dated analogue and basic addressable systems with less cabling, better connectivity and in-built intelligence to make setup as simple as possible. Finally, this was the first installation and project conducted with our distributor, Vesteknikk, which demonstrated the capability of our partnership.