Large-scale refrigeration systems are an integral part of many industries, such as cold storage, petrochemical refining, and food processing. In such applications, Ammonia is the most common choice of refrigerant due to its effective physical properties and low freezing point, making it perfect for refrigeration uses. As ammonia is extremely dangerous to life and health at a concentration of 25ppm (8hrs) and 35ppm (15 minutes), it is critical for ammonia gas detectors to be used in such applications to maintain the safety of the plant and those in the vicinity.

Why is Ammonia Suitable for Refrigeration?

The physical properties of ammonia make it 3-10% more efficient than other refrigerants, according to the International Institute of Ammonia Refrigeration. Refrigeration grade ammonia, or anhydrous ammonia, contains almost no water. With it being 99.98% pure, this ensures that it will not be subject to freezing in refrigeration plants, making it effective as a substitute for CFCs and HCFC’s.

Moreover, Ammonia breaks down in the air quickly and does not damage the ozone layer, unlike CFCs. With an Ozone Depletion Potential (ODP) and a Global Warming Potential (GWP) of zero, refrigeration companies no longer need to worry about the detrimental environmental impacts of their refrigeration gases.

Refrigeration Engineer compelting Safety Checks

Additionally, Ammonia-based refrigeration systems are highly effective because:

- They are significantly cheaper than those that use CFCs as narrower diameter piping can be used.

- The gas itself is substantially cheaper than CFCs or HFCs.

All of the benefits listed above are making ammonia one of the primary gases for use in refrigeration. And with this widespread use comes the need for Ammonia Gas Detectors.

Why Are Ammonia Gas Detectors so Important?

In the cycle of a refrigeration system there are 4 processes: compressing, condensing, restricting, and evaporating. Ammonia is likely to leak during the evaporation stage. And due to the low temperature it reaches at the evaporation stage, it will appear as a vapour cloud upon leaking. This will generally be low lying as it is heavier than air, meaning that large masses of this vapour can build up unknowingly. However, since ammonia has a low boiling point, it turns gaseous at room temperature. Thus, this high level of Ammonia will begin to rise towards the breathing zone as it turns gaseous. And with a STEL of just 35ppm, personnel can quickly become over exposed to this toxic substance.

Alternatively, ammonia can also leak during the compressing, condensing and restricting stage. The compression stage in particular requires large amounts of ammonia gas. This again can put personnel at risk if these large quantities were to leak.

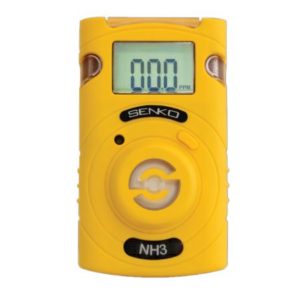

refrigeration supervisor with portable ammonia detection

Any ammonia-based refrigeration system can create the risk of accidental exposure to high concentrations of ammonia, therefore implementing ammonia gas detectors are essential to ensure the health and safety of the personnel and refrigeration plant.

Ammonia gas detectors are employed to sense ammonia for early detection. These detectors notify of the presence of an ammonia leak before there is a risk to health and safety. This means that the leak can be repaired quickly and appropriate safety measures can be taken.

To find out more about the dangers of ammonia, check out our gas page here.

Ammonia Gas Detectors from IGD

At IGD, we have a range of ammonia gas detectors, in both fixed and portable varieties to facilitate the fast detection of ammonia and avoid the gas reaching dangerous levels.

The SGT-P portable ammonia gas detectors are the perfect solution for individual protection against ammonia gas leaks. These ammonia gas detectors are extremely lightweight, at 93g and employ innovative long sensor life and robust housing design. Therefore the SGT-P range of ammonia gas detectors can withstand harsh conditions such as those in industrial refrigeration. These are ideal for refrigeration service personnel, entering and exiting harsh environments across the UK and needing a portable device that can withstand these changing environments. The SGT-P series is the perfect durable and affordable, portable ammonia gas detector for personal protection and can be purchased online for next day delivery.

Our TOCSIN 750 series gas detectors can also be used as ammonia gas detectors and allow for gas detection in a wide array of areas and environments. This series includes the 750 safe area gas detector, 750X ATEX rated gas detector and 750S aspirated gas detector.

Our TOCSIN 750 series gas detectors can also be used as ammonia gas detectors and allow for gas detection in a wide array of areas and environments. This series includes the 750 safe area gas detector, 750X ATEX rated gas detector and 750S aspirated gas detector.

The 750S has minimal moving parts and are almost silent, meaning they require very little maintenance and can detect gases up to 20m away. These are ideal for freezer rooms, industrial refrigeration plants and compressor areas, as the detector can be placed in an easy to reach area and sample from the area up to 20M away.

The 750X is particularly ideal for refrigeration environments due to its ATEX rating and environment proof exterior. This allows the detector to be placed in particularly harsh or fluctuating environments and still perform to the highest standard, ensuring plant protection throughout its life.

The 750X is particularly ideal for refrigeration environments due to its ATEX rating and environment proof exterior. This allows the detector to be placed in particularly harsh or fluctuating environments and still perform to the highest standard, ensuring plant protection throughout its life.

The 750 safe area can be cleverly placed in any non ATEX environment. With a built-in splash guard, the 750 safe area is ideal for refrigeration. Much like the 750X, it will not be affected by dirty environments or accidental splashes, ensuring your device is working as it should. Additionally, the 750 safe area housing is significantly cheaper, saving on the potential costs of an ATEX rated housing where it isn’t required.

The 750 safe area can be cleverly placed in any non ATEX environment. With a built-in splash guard, the 750 safe area is ideal for refrigeration. Much like the 750X, it will not be affected by dirty environments or accidental splashes, ensuring your device is working as it should. Additionally, the 750 safe area housing is significantly cheaper, saving on the potential costs of an ATEX rated housing where it isn’t required.

Check out of one our case studies here to see just how well out 750 safe area gas detectors fit into a refrigeration environment.

Check out of one our case studies here to see just how well out 750 safe area gas detectors fit into a refrigeration environment.

Finally, all our TOC-750 series gas detectors can be fitted with our ground-breaking ionic ammonia sensor technology. Our detectably better ionic ammonia sensors can operate for 5 years and will recover after large NH3 leaks occur, unlike the standard electrochemical sensors on the market. This is hugely cost efficient and convenient for all of our clients, reducing the hassle of replacing sensors and making gas safety simpler for you and your plant.

Pictured: our long life Ionic ammonia sensors. 5 year life time and do not self deplete when detecting ammonia

Unlike current alternatives, our ionic sensors can operate in harsh conditions as low as -40°C and do not self-deplete when sensing ammonia. Massively increasing the operational lifetime of your sensor as it can operate efficiently with background levels of ammonia and still last 5 years, ensuring you have accurate and reliable NH3 detection for longer. Click here to find out more about these revolutionary new sensors.

Contact IGD Today

Call or email us today to find out more. Our gas detection experts are on hand 5 days a week to answer any queries and to help you become detectably better in your gas safety. Alternatively, use the chat function on our website to get in touch with one of our team now. This fast and easy to use service can answer any of your questions in a matter of minutes.