Detecting Oxygen and Carbon Dioxide in a Laboratory – Q&A With AzoNetwork

IGD recently conducting a Question & Answer session with AzoNetowork covering important questions regarding gas detection in laboratories. Our Managing Director undertook the interview discussing important topics within gas safety in laboratories. Topics such as: Why it is important to measure gases like Oxygen and Carbon dioxide in a laboratory and What our gas detection equipment can offer to clients. Read our full Q&A below. If you also wanted to learn more about our gas detection solutions for labs, we wrote an article on this which you can see here.

[AZO] Can you give a brief overview of International Gas Detectors and the work you do?

[IGD] IGD was founded in 1917 to provide gas safety solutions for the mining industry and later the oil and gas industries. Over the years the mission has not changed just the range of industries and applications for which we provide protection. Today we provide gas detection solutions for over 400 gases and vapours into a wide range of applications. Just because you can’t see it, smell it or taste it does not mean a gas hazard is not present and that’s where we do vital work to protect.[AZO] Why is it important to measure gases like oxygen and carbon dioxide in a laboratory?

[IGD] In any activity, it is about understanding the possible risks and taking steps to minimise those risks. If your handling raw chicken then you wash your hands before eating your crisps. So you understood the risk and you mitigated them. So we all breath Oxygen and exhale and CO2 in our breath, so what’s the issue? Again its about education and understanding the hazards and mitigation steps to take. Laboratories commonly use both gaseous and liquid Nitrogen in many processes. Spills of liquid Nitrogen or leaks of gaseous nitrogen can reduce the Oxygen level by diluting the atmosphere. The British Compressed gases Association (BCGA) publishes several guidance notes and ACOP’s (Approved Codes of Practice). These specifically state that “no-one should be exposed to an atmosphere containing less than 19.5% Oxygen“. Liquid Nitrogen can present particular hazards as 1 Liter of liquid Nitrogen will vaporise at room temperature to produce 696 Litres of gaseous Nitrogen. So you don’t need much of a liquid spill in a closed room to have a depleted Oxygen level very quickly.

Carbon Dioxide is also freely used in labs. Many people only consider CO2 as a potential asphyxiation hazard but this is by far not the only risk. The UK health and safety executive list CO2 as a toxic gas hazard with a low alarm at just 0.5%. Consider that in a typical busy office the CO2 level can easily reach 1200ppm (0.12%) just by the action of people breathing out CO2 . As you can see that a small leak can easily breach the health and safety directive EH40. Similar to the liquid Nitrogen example, labs commonly use dry ice (solid form CO2). 1Kg of dry ice will liberate approximately 508 Liters of gaseous CO2. So a few kilograms of dry ice left unconfined will generate quite a hazard. Another issue here is that EH40 details a recovery period to be calculated for people exposed to the published levels. This is often overlooked and a reason why early detection can be so vital.

In each case, if you are not monitoring the atmosphere you have no idea what gas levels might be present. When you use a material every working day it is very easy to become complacent. Gas detection correctly deployed provides early indication against developing hazards allowing appropriate actions to be taken to protect people.

[AZO] The 2-Wire Gas Detection system detects carbon dioxide at the ppm level rather than %v/v level. Why is this beneficial?

[IGD] We do also detect for CO2 at percent levels for some applications but our experience shows ppm-level detection to be far more useful.To begin with, UK legislation set limits for short term exposure at 1.5% and long term exposure at 0.5%. Most people forget that the legislation also requires a recovery period post-exposure. Setting alarms below 0.5%, by using a 5000ppm range detector, allows for earlier detection of developing problems ensuring legislative levels are not breached and issues can be dealt with more promptly.

Government guidelines further reinforce this. Guidance in publications such as BB101 set ppm level limits for CO2 effectively requiring detection ranges at 0-5000ppm.

Percentage range detectors are relatively insensitive requiring a degree of precision when placing the detector for it to be effective. As the 5000ppm range detector is more sensitive it requires less accuracy when placing for it to be highly effective.

Remember if you are not monitoring for the gas hazard in question you will have no idea if you are compliant or not to HSE requirements.

[AZO] How is International Gas Detectors’ 2-Wire Gas Detection System well suited to detecting both carbon dioxide and oxygen in a laboratory?

[IGD] Our addressable systems digitally communicate real-time values, there are many benefits to this technology.Communicating and powering detector nodes using a single cable pair may not seem like much but it is a huge saving on installation. When budgets are tight this means that for the same budget you get more actual detection for your money, not paying for lots of cabling that you are not interested in. Allied to that, the detectors themselves can have audible visual alarms built-in, saving further and clearly showing which detector alarmed.

Calibration is held on the detector head making it very easy to swap out detector heads or change gas types. If your renting lab space then being able to swap detectors quickly to cover differing gas hazards easily makes a huge difference to safety and costs.

Pictured: Tocsin 635 Controller

Of course, the systems communicate digitally so you get the same numbers everywhere. This is a big failing of older analogue technologies where conversion errors mean displays on a detector vs the control panel or remote display are rarely the same.

Intelligent controllers allow alert texts or emails to be sent. Event logs can be stored and emailed giving owner-operators control of the data, what happened when and to what level.

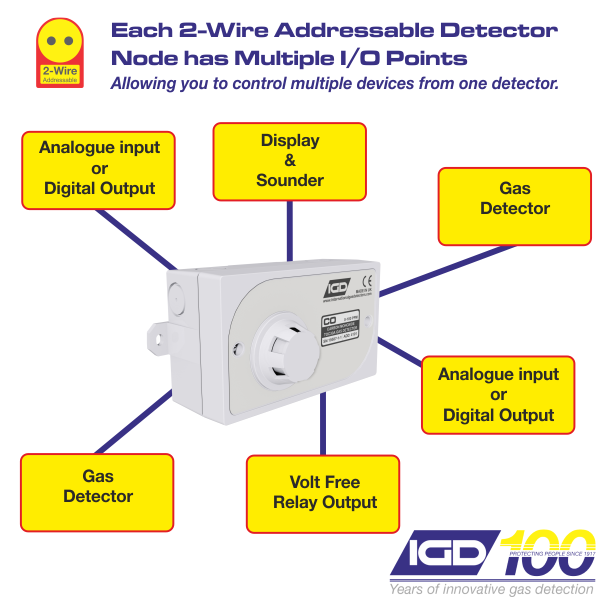

Our 2-Wire Addressable systems can be far more than just gas detection. Each detector node can read in signals from other third-party devices. This allows you to read from sensors for parameters such as pressure, flow, temperature, etc and report back to the controller. So for the investment to cable an IGD system you can leverage much more than just gas detection. Digital connectivity from the controllers then gives access to any required parameter for reporting, controlling or alarming.

[AZO] What are the benefits of additional I/O capability per detector for gas detection in the laboratory?

[IGD] Each detector has several additional I/O points available. As discussed this lets you leverage the installation costs to include other sensors or control points. For example, if a lab needs to alarm should the differential air pressure fall this is simple to add as additional inputs to the nearest detector node. Alarm actions can then be simply programmed at the controller. No need for another controller, cabling, and infrastructure just include it as part of the detection system.Therefore, you should stop thinking of it as just a gas detection system, this now becomes your general detection system for all sorts of parameters such as: temperature, pressure, airflow, etc. Allied to that, you also have outputs available on each detector which can be used to control, valves, alarms, ventilation for example. So again, less infrastructure and cost required to achieve the desired result and a flexible system. As the requirements change it is very easy to add or take away from the system as required with minimal impact.

[AZO]What are the reporting features of International Gas Detectors’ systems and how do they compare to other gas detectors on the market?

[IGD] The modern world is all about connectivity, sharing and reporting data, this is where IGD systems show a big difference. Traditional gas detection systems leave managers in the dark. Isolated detection systems mean managers can have no idea if and when alarms happen, what state the systems are in and if staff abuse them to make life ‘easier’.With IGD systems it is all about ensuring maximum safety and making sure vital information is available to the right people at the right time.

IGD Controllers support report real-time data and event logging which include all interaction with the controller. Pass-codes and lockouts provide managed control over who has access to the gas detection system. Add the GSM option, now alarms can be emailed and texted to key personnel. Status reports and event logs can be emailed at prescribed intervals putting managers in control. Now you know what happened when and the calibration status of your system. Detectors are already networked to controllers but you can also network controllers either to site BMS systems or to an IGD HMI controller. The HMI module allows you to see data from all networked controllers in an easy to digest format. Our HMI can then also be networked. HMI’s also allow data logging and trending. Providing access to data when you need it, where you need it, allowing users to take appropriate actions.

[AZO]How easy it is to use your systems, do you provide training for them?

[IGD] Training is key to what we do. IGD realised this many years ago providing CPD approved training courses that are now available online. So users and engineers can access training modules anywhere in the world at a time to suit them. Most of the hazardous gases we monitor for are odourless and tasteless and can’t be seen, so it can be hard for users to believe the hazard is real. Therefore, training at all levels becomes essential to raise awareness, know what you are dealing with and choosing the correct course of action for the best outcome. That’s true whether you are working in where there may be a hazard, checking if an event has cleared or servicing our equipment.

[AZO] What level of support do IGD provide to clients?

[IGD] Clients come to IGD with Gas Detection applications and its our job to provide effective solutions for them. Key to doing that is supporting our clients at each stage of the process. We are there to help to the level of support required so clients are comfortable with the decisions they need to make. At an early stage this may be reviewing with them what is required, providing gas safety risk assessments and advice. As a project progresses we provide easily understood proposals showing how we can help mitigate their gas risks. If we are lucky to be involved with a project then we can provide turn key solutions or training and support to allow others to effectively install our equipment. Post installation we provide training support for the end user and their service teams if they want to undertake servicing activities themselves. All of this is backed by IGD’s online CPD approved training.[AZO] What is next for International Gas Detectors?

[IGD] We strive to continuously improve our technology and systems all the time as an on-going process. For us, the next big development will be to cloud the data from our systems. This then gives clients a real-time view of their systems wherever they are. It also provides service teams with a vital next step to further improve support allowing much more effective preventative maintenance.Want to stay up to date with the latest news and articles from us? Follow the link to sign up to our Monthly newsletter Insights into Gas Detection.