The answer is that in most cases you do not need a gas sampling system. Anything that gets between the detector and the gas it is trying to measure will increase the potential unreliability of the measurement and also increase the detection time. In general, you want the gas detector directly in the atmosphere it is measuring and as close to the leak source, for the best and most reliable result.

However there are situations where this is not practical and this is where the sampling gas detector comes into its own, providing a unique solution.

Gas sampling system, also known as an aspirated gas detector, work by drawing a gas sample from the desired detection point to a remotely located detector. Usually the sample is drawn through tubing and some kind of pump is used to move the sample gas stream.

Unfortunately, all samplers suffer from the same problems:

- The sample line (or tubing) can become blocked, which means the flow must be monitored adding complexity to the monitoring system.

- To help prevent line blockages, inlet filters may be added. However, these will need continuous maintenance and either training for clients, so they understand when and how to replace filters or more frequent gas detection service visits.

- The tube length introduces a lag time to detection. This means that there is a time increase from a gas leak to the detector alarming. The time increases with increases to the tube length.

- The gas being detected may adsorb onto the tubing, loosing ‘reading’ to the tube walls and potentially becoming an undetected gas hazard.

- The pump may have valves, seals, pistons or diaphragms requiring maintenance and again may result in more frequent service visits and increasing cost of ownership.

- Some sampling gas detectors may share one detector to a number of sample points. This increases lag time, increasing the delay in alarm activation and adding more complexity with valve arrangements.

You must also take into account that with any gas detector the reading is only true at the point of detection. A sampling gas detector is no different. The reading is only true for the point that the sample gas enters the tubing system. Sampling does not increase the detection range of the system.

So Why Would I Want to Use a Gas Sampling System?

There are some applications that benefit from using a aspirated gas detector despite the added complication and not all samplers are equal. So, here are some applications where samplers add value:

a. Clean rooms. Gas detectors can be an issue in clean rooms, either as dirt traps or bug traps. Sampling detectors can have small neat sample points limiting this issue.

b. Access problems. It may not be practical to fit a standard diffusion gas detector in the location required. If the detector is located high up, then access for maintenance is a problem. Similarly, sumps, bore holes and drains to name a few, may not have space or be an appropriate environment for a diffusion-based detector.

c. Space Problems. There may not be space for a normal diffusion-based detector, for example glove boxes and fume cupboards.

d. Environment. The environment may be too severe for example high temperature or extreme low temperatures, such as drying ovens, freezers and refrigeration units. Again, an aspirated gas detector can draw a sample from the harsh environment; processing the gas stream to be more tolerable to the detector.

In all these cases a sampling gas detector correctly matched to the application and gas type will offer a more appropriate solution.

IGD’s Gas Sampling System Solutions

So how can IGD help? we offer two sampler solutions depending if the environment is a zoned hazardous area or not.

TOC-750S Series Aspirated Gas Detector

Our safe area, non-ATEX, 750S series of samplers offer a unique solution to the issues that face typical sampling gas detectors currently offered on the market.

- Virtually no moving parts, thus increasing reliability over conventional pump-based systems. Furthermore IGD’s piezo pump technology uses a high reliability diaphragm to move gas at 1L per minute. This means no valves to block, no elastomers to degrade nor react with the sample.

- 750S module continuously monitors the flow rate and alarms on blockages for added safety.

- PTFE Tubing options limits sample loss.

- Hydrophobic filters block harmful water ingress

- Long life sample point filters, minimise maintenance required.

- By using a second pump, the intelligent module can be setup to automatically draw a zero sample for an automated zero. In addition to this, for Oxygen sensor you can automate the calibration. This then extends maintenance periods and adds excellent stability.

- We have a range of filter options for applications such as clean rooms, spiral freezers, glove boxes and sumps etc. Thus making the 750 Sampling gas detector a flexible option.

- Samplers can be integrated into IGD’s 2-Wire Addressable Systems. This dramatically reduces installation costs and provides real-time digital readings.

- Small footprint, reducing space required to install the aspirated gas detector.

- Can draw a sample from up to 20M away.

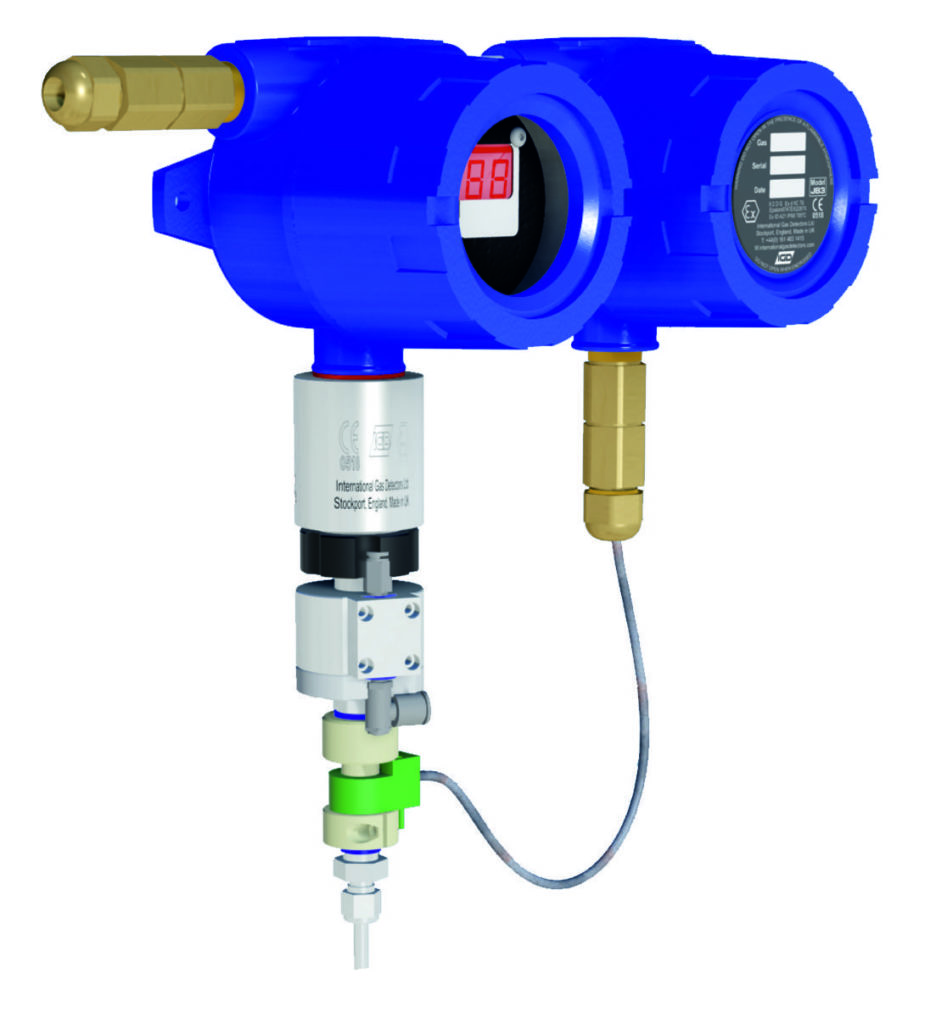

ATEX Aspirated Gas Detector Options

The 750S series of samplers are typically used for non-ATEX applications. Where flammable atmospheres may be present then you will require ATEX rated electrical equipment. For ATEX applications IGD’s EMS samplers can be fitted to any of the IGD range of ATEX rated gas detectors. In the current range this includes 903 Series, 102 Series and 750X series gas detectors. The EMS sampler offers an effective ATEX sampler solution:

- No moving parts. Our EMS uses air driven venturi pump system to draw a gas sample.

- Minimal air requirements

- Flow failure monitoring, to provide enhanced safety.

- Can sample from long distances, up to 50M away.

- Wetter parts are chosen. This is because they are highly corrosion resistant.

- Works with any IGD ATEX gas detector.

- Unaffected by entrained moisture.

Therefore if a gas sampling system is the correct solution for your application; then IGD can offer a range of options. Our systems provide positive benefits including: safe operation, minimal maintenance and long reliable service life. Contact us today to find out more:

E: sales@internationalgasdetectors.com

T: +44 (0)161 483 1415