Recently, IGD collaborated with Jigsaw Controls on a project that saw the need for a standalone gas detector transmitter in an ATEX zone 1 potentially flammable atmosphere. Jigsaw Controls client required a continuous gas monitor to detect for methane and hydrogen sulphide in habitat shelters. IGD’s solution was to provide our advanced TOC-903-X5 dual gas detector transmitter in this area, allowing for safe working in an environment that would otherwise be hazardous. Read on to find out more.

Who are Jigsaw Controls?

Jigsaw controls are a Stockport based company primarily supplying electrical equipment for use in areas at risk of fire or explosion hazards (hazardous areas). They also design equipment for general purpose safe area applications as well as bespoke equipment for unique applications. Thus, you can be sure that you will find your electrical equipment requirement at Jigsaw controls. Jigsaw pride themselves on minimising their environmental impact whilst also promoting the highest standards of health, safety and ethical working practices. They are committed to providing this for both themselves and their clients, providing training courses and maintenance services to encourage clients to be as safe and ethically conscious as possible.

This commitment to improving the safety of people around the world and providing the best available equipment for this aligned perfectly with IGD’s ethos, making this project a huge success.

Click here to learn more about Jigsaw controls Ltd.

Why did this Area need ATEX detection?

Jigsaws client had quite a complicated process on site, requiring the best technology available. The specific process on site is known as a welding shelter or habitat station. These are used typically on oil rigs which are a hot spot for flammable gases, making welding a particularly dangerous task to complete. The tents make this process safer, by pumping them full of clean air to ensure that these tasks can be completed safely. Machines known as pressurisation control systems pump clean air into these areas to help control the air quality in these tents. And the client needed gas detection to ensure that no hazardous gases were being pumped into these safe areas.

This site had a combined hazard of both methane and H2S, and the client wanted to make sure that the welders weren’t at risk to any of these hazards. Not only would the presence of methane make this environment potentially explosive, but the presence of H2S would mean that personnel would also be at risk of poisoning. Thus, they needed a solution that would protect from both hazards in a compact and ATEX rated format.

IGD’s Solution?

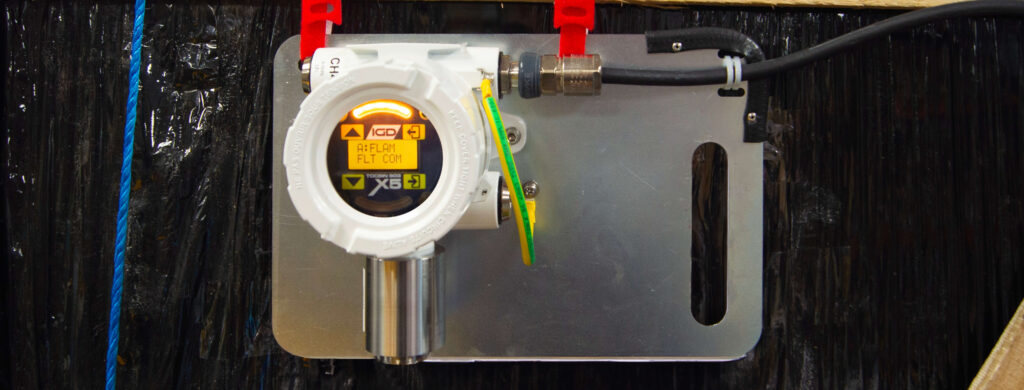

IGD decided to provide Jigsaw Controls and their client with the 903-X5 gas detector transmitter, as this kept in line with Jigsaw controls principal of “making things better” by providing the best technology the market has to offer. IGD installed these gas detectors transmitters into the pressurisation control systems ready to send off to Jigsaw Controls Client.

Dual sensor capability

One of the main benefits that the X5 offered was its dual sensor capability. Normally, due to the sites multiple hazards, machines like this would need to be fitted with 2 separate detector heads, but the 903-X5 gas detector transmitter removes this requirement. Only one X5 needed to be installed in each machine, as it could detect for both methane and hydrogen sulphide efficiently. This drastically reduced the cost of product, as well as the cost and time of installation, providing a detectably better product without compromising on price.

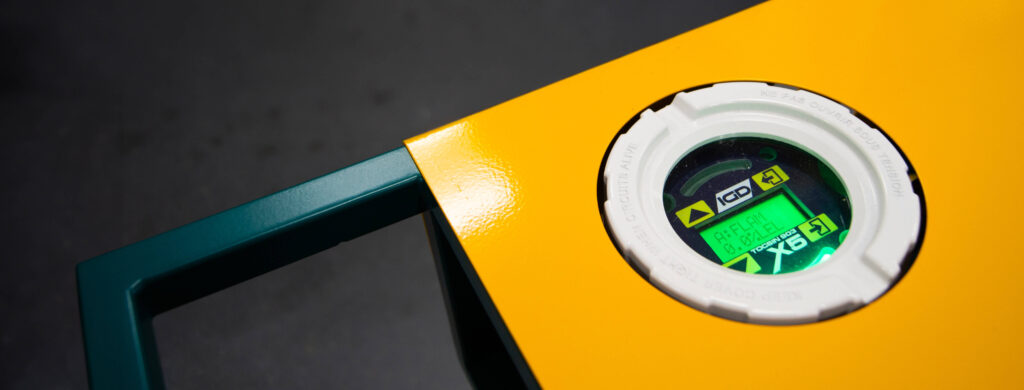

Non-intrusive display

What’s more, The TOCSIN 903-X5 gas detector transmitters feature local non-intrusive display, onboard relays and ATEX certification. This meant that the client could setup the detectors and calibrate them locally without requiring a hot works permit typically needed in an ATEX environment. This was thanks to our intuitive non-intrusive display. Our ATEX certification also ensured that the devices were fit for purpose for both Jigsaw Controls and their client.

Auto system shut down

The 903-X5 was able to easily integrate into the process the pressurisation control system was performing and could shut it down when needed. The gas detectors sniff for gas in the ducts of this machine, and once a gas is detected, the on-board relays of the 903-X5 gas detector transmitter shut down the supply of air. This guarantees that the system is shut down is a hazard is detected, by removing the possibility of human error and reduced the time consumed in a manual shut down. This automation therefore drastically increased the safety of personnel. Furthermore, to keep the sensor easy to access for calibration and servicing, the gas detector transmitter monitored through a pitot tube. Thus, not only did this provide accurate and reliable detection, but it also made the jobs of the service engineers easier.

The MK8 Pellistor

Finally, we supplied Jigsaw Controls and their client our leading MK8 pellistor (catalytic) detectors. These featured the most poison resistant pellistors on the market. IGD’s pellistors also have the longest operational lifetime on the market. This ensured Jigsaw Controls and their client had a reliable and long-lasting flammable gas detector transmitter. Find out more about our leading MK8 Pellistors here.

The End Result

Through this collaboration, we were able to give the client a versatile, high quality and reliable ATEX gas detector transmitter. IGD utilised our over a century of gas detection expertise to provide a detectably better product, as well as installation and servicing for Jigsaw Controls.

Both Jigsaw Controls and the client were very happy with this addition to their pressurisation control systems, providing them both with peace of mind that their workspaces are safe for their team and their company. The X5s are now an integral part of these machines, being installed in each one manufactured by Jigsaw Controls.

Director of Jigsaw controls Ltd. Paul Wilks had this to say about the collaboration with IGD: “This system is a perfect example of how we work together, not just with clients, but also with our suppliers, to ensure the best possible product for the end user. This collaboration, from day one, ensures everyone shares the same end goal – quality, safety, reliability, and simplicity of use for operators. It’s fundamental to how we work as a company – that we see ourselves as an extension of our client’s team, and look at the end result from their perspective. We think of things that would make our life easier if we were using the system and then incorporate them into our design and manufacture.”

Need a Gas Detection System like this?

Contact IGD today for all your gas detection needs. With over a century of experience in gas detection, we can provide a detectably better solution perfectly suited to your requirements. With full service, training, support and installation straight from the manufacturer. We have a range of gas detection options available, from fixed to portable, so get in touch today to find out how IGD can help you become detectably better in your gas safety.