How Do We Monitor VOC’s and Why Do We Use VOC Detectors?

VOC’s or Volatile Organic Compounds are organic chemicals that have a high vapour pressure at room temperature. This results in a low boiling point and thus, a large number of these molecules can evaporate and enter the surrounding air.

Common VOC’s both industrial and domestic:

| Acetone | Industrial Solvent.

Also Nail polish remover, furniture polish |

| Benzene | Paints, adhesives, petrol car exhausts |

| Formaldehyde | Some plastics, adhesives, floor coatings, green timber |

| Butanal | Barbecue emissions, candles, stoves, cigarettes |

| Ethanol | Glass cleaners, laundry detergents, dishwasher detergents, all alcohol (wines, beers, spirits) |

| Toluene | Paints and industrial coatings |

| Xylene | Paints, industrial coatings, combustion vehicle emissions |

As can be seen from the table VOC’s are extremely common and can be from surprising sources. Each VOC comes with its own exposure hazards and reasons they need to be monitored. These can be found by accessing each materials Material Safety Data Sheet (MSDS). But how are these monitored? And why do we monitor these gases? These questions will be answered below to help provide a basic understanding of VOC gases and the dangers.

Why do we use VOC detectors?

There are a number of reasons as to why a VOC detector may be needed, one of these is the long term health effects on people. VOCs such as benzene can cause cancer if long exposure occurs, and other VOCs can be lung irritants. Although not acutely toxic, many VOCs can cause long term health issues. COSHH regulations summarise the occupational exposure limits amongst personnel working with VOCs. Therefore, to adhere to health and safety regulations, as well as to ensure the health of personnel, a VOC detector is vital.

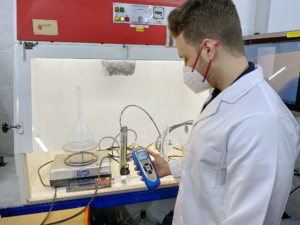

NEO single gas VOC detector used in a fume cupboard

Recent changes in climate laws may also warrant the use of a VOC detector. The Paris Climate Agreement is an international treaty introduced in 2016; Its goal is to limit global warming levels to well below 2, preferably to 1.5 degrees Celsius, above pre-industrial levels. Thus, they aim to restrict the amount of greenhouse gases emitted by each nation as soon as possible to meet this target. Other regulations include the environmental permitting regulations (EPR) for England and Wales. These again restrict the number of harmful gases, by listing the industrial processes that emit harmful gases and issue a permit to prevent or minimise pollution using Best Available Techniques (BAT). Thus, warranting the use of a VOC detector to monitor and control these gases.

Therefore, VOC detectors are useful in a wide range of situations and are becoming more and more relevant due to the growing environmental concerns. Knowing which detectors to use is a vital part of the process of using VOC detectors. At IGD, we have over 100 years of experience in gas detection, coupled with our specialist knowledge in PID detection, we are able to offer an outstanding VOC detector range for any application.

How do we monitor VOC gases?

VOCs are monitored by VOC detectors, and the type of detector needed depends on the application. The types available include portable detectors and fixed detectors, and these can be further subcategorised into the types of those detectors.

Single gas portable VOC detectors

Single gas VOC monitors such as the NEO are used for detection and analysis of Volatile Organic Compounds. This type of portable is most commonly used in hazmat response and arson investigation along with industrial hygiene monitoring. The NEO offers the most stable PPB level in this class of detector and is smaller and lighter weight than comparable portable VOC detectors currently on the market. The NEO comes equipped with a pumped feature and is protected by a durable rubber boot. Ideal for use in harsh environments, the NEO can offer easy, portable sampling detection when required. This device can come in a Benzene model or a PPB model, for full versatility in any VOC application.

NEO single gas portable VOC detector

Multi gas portable VOC detectors

Multi gas VOC detectors such as the POLI can monitor up to 5 gases at once. This is ideal for applications such as confined spaces, wastewater, effluents and any other application, requiring multiple gas detection for personal protection. You can find out more about using a VOC sensor in effluent monitoring here. The POLI offers a wide range of plug-and-play smart sensors, equipped with a Micro USB for easy on-the-go charging capability. This smart device is also equipped with a unique man down alarm. This VOC detector is ideal for ‘on the go’ applications as it can easily charge whilst travelling and can keep track of the safety of personnel within a confined space.

POLI Multi gas portable VOC detector

Fixed safe area VOC detection

Devices such as the 750 VOC detector are created for safe area applications (Non ATEX). This includes applications such as Laboratories, education, gas bottle stores, goods storage and similar environments and applications. The 750 PID offers world leading PID sensor technology, equipped with a non-electrode UV lamp offering long lamp life and the ability to curtail sputtering. The IGD PID sensor also contains a unique electrode stack design, negating the common issue of humidity. TOC-750 is an ideal choice in any suitable application as the cost of ownership is significantly reduced whilst the performance of the VOC detector is increased.

Safe Area PID VOC Detector

ATEX rated fixed VOC detection

This sensor is also available in ATEX format as the TOC-750X and 903-X5 models. These VOC detectors are ideal in applications such as hazardous chemical storage, fuel storage, oil and gas applications, coating processes, adhesive manufacture to name just a few. The 903-X5 can provide reliable VOC detection in addition to one other gas, perfect for applications requiring multiple gas detection in a fixed format (e.g oil and gas). These detectors are equipped with IGDs latest ATEX housings for use in zoned hazardous areas. It is resistant to corrosive gases and have enhanced ingress protection for dusts, liquids and gases. Both VOC detectors can easily be integrated into existing BMS systems, ideal for emergency ventilation needs in these applications.

ATEX rated fixed VOC detection

Alternative Fixed VOC detection

Sampling detectors are necessary in some applications, particularly cleanrooms and pharmaceutical environments. The TOC-750S series samplers utilise our revolutionary piezo pump technology. This makes the VOC detector significantly smaller than traditional samplers, as well as being substantially quieter and with far fewer moving parts allowing a big reliability gain over competing products. This also allows the device to continually monitor its performance and enables continuous detection. A wide range of accessories can be fitted to this VOC detector, thus making it ideal for clean room detection, as the sampler doesn’t need to be in the cleanroom to detect and can be fitted through the wall, specified to the clients’ requirements.

TOC-750S Sampling PID Detector

All the above fixed VOC detectors are fitted with the revolutionary VOC sensor from IGD, and the TOC-750 series are all implemented onto 2-wire technologies. This significantly reducing the costs of installation by around 70% and reduces the amount of cabling and devices needed for installation and improves reliability.

Contact IGD

Contact our team here about IGDs detectably better gas detection range. IGD can offer the complete gas detection solution with our specialist knowledge, thus you can be reassured you are receiving a competent and high quality VOC detector.