IGD were recently approached by a cement manufacturing company to implement Hydrogen Chloride gas detectors within their facility. Time was of the essence as they needed to begin the works on site shortly. IGD were able to meet the deadline and provide them with a detectably better solution. Our solution of the 750X and the TOC-635 PLUS met their requirements and provided them with a reliable gas safety system to ensure the safety of their team. Read on below to find out more.

Why Were Hydrogen Chloride Gas Detectors Required?

This company manufactures cement-based products for the construction industry; this particular application is to provide a range of finishes to a standard cement-based product to show texture based on represented material and or age as required by the finish.

To provide these forms of finish, they apply 25% strength Hydrochloric Acid to partly cured concrete elements. This is to help in stripping away the smooth surface and to expose the aggregate, used as the premier material for cement manufacturing. During this process, a cloud of Hydrogen Chloride can occur. Typically, this process is performed outside, thus not warranting the use of Hydrogen Chloride gas detectors.

Concrete road curbs at the factory for the production of cement products, paving slabs, construction material for a new sidewalk

However, this cement company have built a dedicated building with a fume extraction and neutralisation system to house this process. Therefore, they required Hydrogen Chloride gas detectors to alarm should one of these first line of defence systems fail.

Why is Hydrogen Chloride Dangerous?

Hydrogen Chloride is a highly toxic gas, with a STEL as low as 5ppm. It is extremely corrosive and reacts quickly with water in the air to form cloud of Hydrochloric acid. With this gas being colourless, it is unable to be spotted by the naked eye. However, it does have a distinct strong smell.

At very low levels, Inhalation of HCL over a short period of time can cause throat irritation. Higher levels are far more dangerous, causing rapid breathing and blue colouring of the skin. In severe cases, high levels of exposure can cause throat swelling, suffocation, and death. Thus, to ensure high levels are not reached and there is no risk of this, a Hydrogen Chloride gas detector must be implemented.

Why did this Cement Company Approach IGD?

This company initially approached us as they had been experiencing continual delays from their current gas detection supplier, resulting in months of waiting and delays. Since this was essential to start production on their site safely, they needed a Hydrogen Chloride gas detector solution quickly. IGD were happy to step in and provide them with a quick but reliable solution to suit their needs.

What was our Hydrogen Chloride Gas Detector Solution?

Our gas detection experts decided that the 750X Hydrogen Chloride gas detector with the TOC-635 PLUS panel was the ideal solution for these clients.

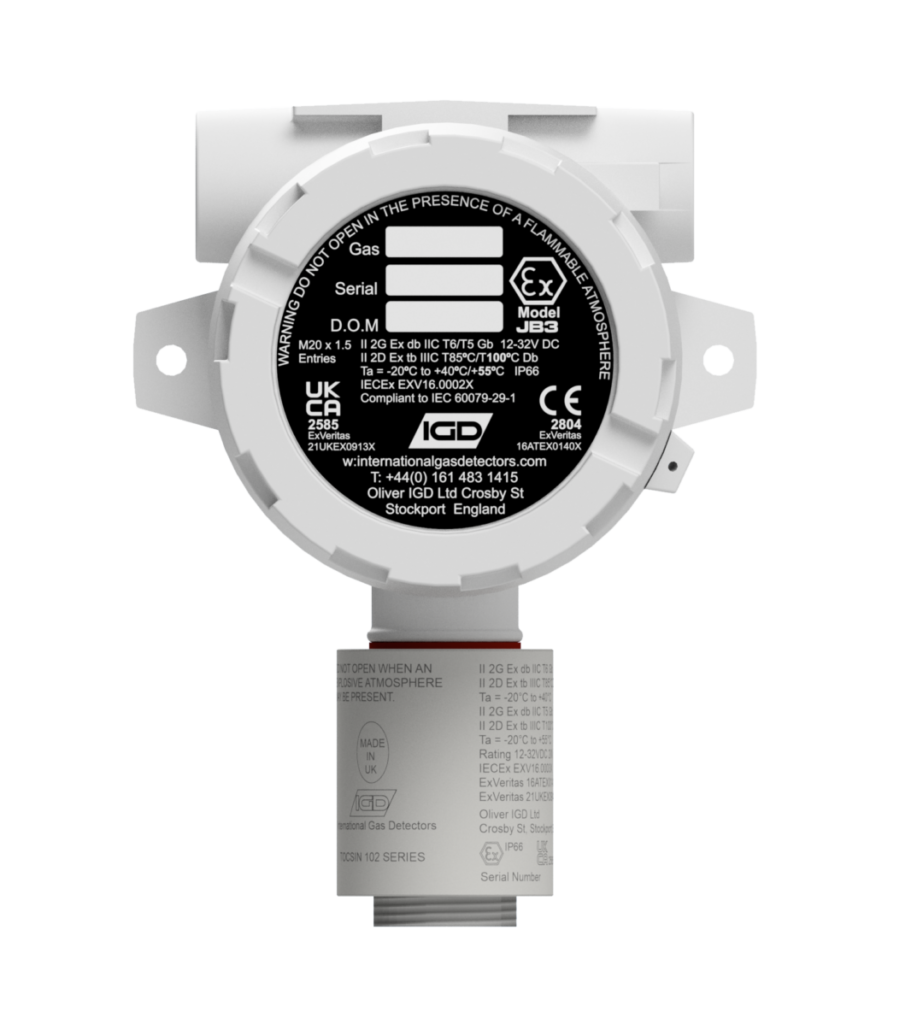

The TOC-750X was perfect for this environment, with its enhanced IP rating, providing protection to the device from harsh environmental conditions common in the cement industry. Thus, providing extra protection for the sensor, reducing upkeep costs through pre-calibrated detector head replacements whilst ensuring their Hydrogen Chloride gas detector is continually performing at its best.

Pictured: TOC-750X Addressable ATEX Detector

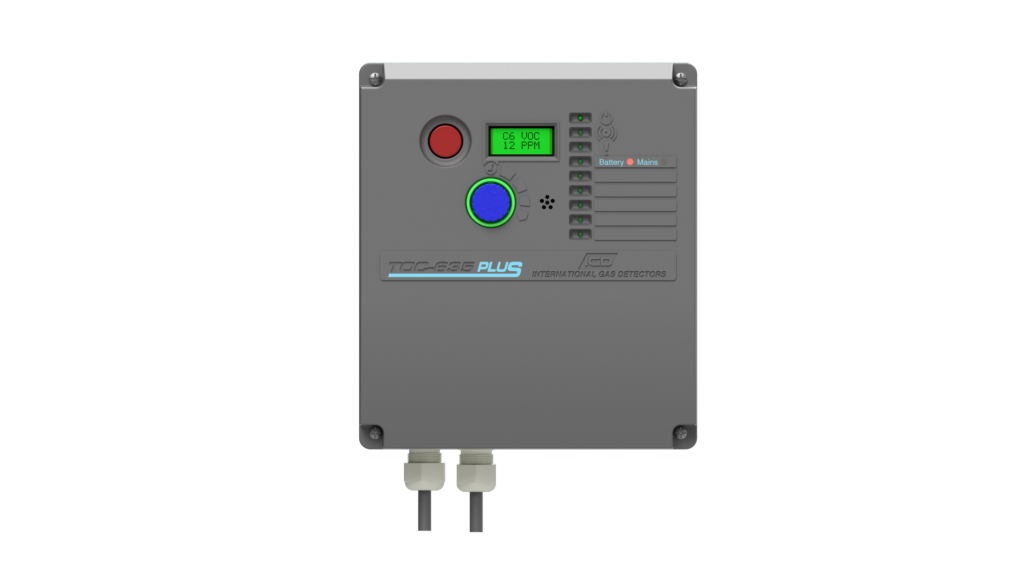

Additionally, we implemented the TOC-635 PLUS panel into this application due to the small number of devices along the system. Not only did this massively simplify the system set up with our 1 click system setup feature, but also the maintenance and calibration. Our illuminated jog wheel operation and 2×8 display enables easy system status at a glance. Therefore, our clients can easily and quickly see if the room is safe for operation.

Pictured: TOC-635-PLUS Addressable Gas Detection Controller

The Result

Overall, the implementation of this system was massively successful for this company. IGD were able to provide the Hydrogen Chloride gas detector and install it within a couple of weeks. Our in-house installation team are fully accredited to CHAS Elite, NICEIC standards and SafeContractor. Thus ensuring the client received a detectably better installation and equipment. This was particularly important for the client, so they were very pleased with this result. With the added benefits of a technologically advanced, reliable system and 10 Year Warranty, they were confident they had found the right solution.

In addition to the quick system set up, IGD will ensure the system is in top working order throughout its life with a customised planned preventative maintenance package. This case study has grown our expertise in the cement production field, allowing us to provide a detectably better service and product to all of our clients within this industry.

Contact our team to find out more about our Hydrogen Chloride gas detector solutions. Not interested in HCL? No problem! We offer a huge array of solutions for over 700 different gases and vapours, and our team of experts are on hand 5 days a week to answer any of your questions.