It is a well-known fact that hydrogen is a common by-product when charging lead acid batteries. Our blog post will help discuss why you need to ensure your battery stores have a hydrogen gas detector present and our [International Gas Detectors] hydrogen gas detector solutions.

It is very commonplace now for both commercial and industrial premises to have battery backup facilities to provide short term backup power, in case of power failure to the building. Such applications can range from emergency care units, data centres, universities, process/manufacturing applications, banking and stock exchanges and many more. Typically, the battery backup facility would utilise lead acid batteries which are continuously charged in a storeroom. They are a good solution to keep critical systems running without the need for costly generators. However, a major issue with lead acid batteries is they produce hydrogen gas which is explosive at 4% by volume in air. This is where the use of a hydrogen gas detector is required. You can learn more about our range of hydrogen gas detection solutions on our application page.

Hydrogen Gas Detector for Continuous Monitoring

As the lead acid batteries will create small amounts of hydrogen as a by-product of its charging cycle; it is key to monitor the area using a hydrogen gas detector. Hydrogen is explosive at 4% by volume in air and typically battery storage facilities are enclosed areas. If a leak goes undetected then this can easily create a potentially explosive atmosphere. In addition, it is also important to note, even if ventilation is present in the room, you cannot just rely on this. Finally, hydrogen is a lighter than air gas, this means that if any leak occurs, the gas will rise and accumulate into the highest part of the room/storage area. A hydrogen gas detector is a key solution for this application for a couple of reasons.

The first reason, you should never solely rely on ventilation to keep an area safe from gas leaks. With every risk assessment there is always a safety gap, as discussed in our article here – Functional Safety and Gas Detection. The safety gap here is what happens if the ventilation fails? Would you know? Also if you are not measuring for the gas how do you know if it is or is not present? A hydrogen gas detector would continuously monitor the environment for any rising hydrogen levels and can also initiate ventilation when required. In addition, the hydrogen gas detector would also alert trained personnel about the rising gas leaks before they become hazardous or explosive.

The second reason, whenever you are dealing with potential gas leaks, either explosive, inert, or toxic it is always best practice to install a fixed gas detector, as these provide 24/7 continuous monitoring. In the case of a battery storage area, these are commonly unmanned areas and as such are usually the place where an accident may occur. The hydrogen gas detector would provide 24/7 continuous detection and can provide remote alarms via text, email or to a site BMS about any rise in hydrogen levels.

IGD Hydrogen Gas Detector Solutions

As a manufacturer of gas detection equipment, we can provide a range of hydrogen gas detector devices to meet your site requirements. As most battery charging and storage facilities do not require explosion proof detectors (ATEX), then our 750 series safe area detector is the ideal solution. If batteries are being charged correctly then most battery technologies are recombining the hydrogen internally. However, as a battery degrades, or the charging cycle is not running at optimum level, the battery will start to liberate more hydrogen than they should (note all lead acid batteries liberate hydrogen to some degree). Therefore, if you are monitoring at lower ppm levels, such as our 0-4000ppm (10%LEL) hydrogen gas detector, you can use the lower detection to spot two things. Firstly, if there is a build-up of hydrogen occurring, the sensor can initiate/increase the ventilation early. Secondly, alerting personnel that there is a problem with the battery or charging cycle. Thus, allowing your team to spot problems well before they become an issue.

In addition, the 750 series safe area hydrogen gas detector can be fitted with a remote calibration port. As hydrogen is much lighter than air then the sensor will need to be placed on the ceiling or alcoves where the gas will accumulate. The remote gassing port allows engineers to easily calibrate the sensors without requiring working at height access.

Finally, our 635 small format control panel is the ideal controller for these applications. Most battery charging and storage facilities are small or enclosed units. Only requiring a small number of detectors. The 635 can have up to 32, 750 safe area detectors interconnected together on a single 2-Core cable highway. In addition, it features built in audible visual alarms and illuminated jog wheel, for at a glance system status. Easy to install, with self-setup and one of the most cost-effective solutions on the market, while providing more flexibility and data compared to tradition 4-20mA analogue and older addressable systems.

What About Portable Units?

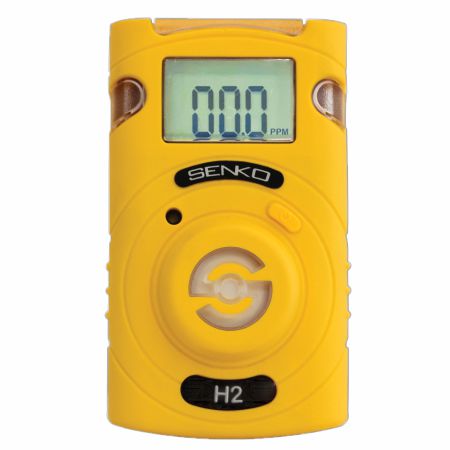

If you are an engineer or ventilation service engineer visiting sites, then you may want to invest in a portable hydrogen gas detector. This is especially useful for engineers who visit several battery storage/charging facilities, as you cannot rely on the site having a functioning or correctly calibrated hydrogen gas detector system in place. The portable will therefore provide a last line of defence for a potential hydrogen gas leak. A portable hydrogen gas detector is also useful for site personnel when used in conjunction with a fixed system. As this allows your team to investigate hydrogen gas leaks that have been reported from the fixed hydrogen detector. This doubles up as alarm verification. The SENKO SGT-P Hydrogen gas detector is the perfect solution and can be ordered online from our store here.

If in doubt always consult IGD before making a purchase. We can provide full project support from gas hazard surveys, site surveys, installation, to ongoing aftercare and service. If you require a hydrogen gas detector contact our team today.