With hydrogen applications on the rise, hydrogen generator safety is now a more important consideration than ever before. Though the future of the hydrogen economy is uncertain, it is clear that ensuring future hydrogen boiler and hydrogen generator safety will depend on the widespread implementation of reliable gas detectors. IGD’s MK8 pellistor detector is the ideal flammable gas detector to ensure hydrogen generator safety, offering a long service life alongside unparalleled stability and poison resistance.

Hydrogen on the Rise

Hydrogen has long been an important industrial gas, playing vital roles in petrochemical processing, chemical manufacturing and as a coolant. However, its role in society is set to change rapidly over the coming years, with more and more applications making use of hydrogen as a fuel.

Unlike other fuels – which are almost all derived from naturally occurring oil or gas – hydrogen is not a naturally abundant source of energy on Earth. However, in contrast to fossil fuels, hydrogen can be produced from ordinary water.

Industrial hydrogen has traditionally been produced by steam methane reforming (SMR), which consumes natural gas in the process. Electrolysis or “water splitting,” on the other hand, can be used to produce hydrogen using nothing but electricity and water. Powering electrolytic hydrogen generators with renewable energy provides an efficient and versatile way of storing renewable energy in the form of hydrogen gas, offering a solution to the problem of large-scale energy storage in a distributed renewables-based energy grid.

Hydrogen is extremely energy-dense (much more so than batteries or capacitors) and can store energy over long time periods without losses. In addition, reclaiming the energy from hydrogen gas using fuel cells produces only water vapor in the process. Hydrogen could play a major role in decarbonizing the world’s energy supply if effective hydrogen boiler and hydrogen generator safety measures are implemented.

As a result, the hydrogen economy is undergoing massive growth, with global hydrogen demand predicted to reach up to 500 million tons per year by 2050.1 In the UK, plans are already underway to add hydrogen (at up to 20%) to the mains gas supply within the next 10 years.2,3

Hydrogen Boiler and Hydrogen Generator Safety Consisderations

As hydrogen starts to play a more prominent role in energy generation, transfer and storage; electrolytic hydrogen generators (which produce hydrogen through the electrolysis of water) and hydrogen boilers (which heat water through the combustion of hydrogen) will become more commonplace – and hydrogen generator safety considerations will become more important.

Despite hydrogen’s many advantages and applications, the fact remains that it is a dangerous gas. Hydrogen generator safety is adversely affected by the flammability of hydrogen in air at concentrations between 4% and 75% by volume (for comparison, methane is flammable in air only in a proportion between 4.4% and 17% by volume). The amount of energy required to ignite hydrogen in air is also much lower than that of other fuel gases such as methane or propane.4 In addition, leaks are of special concern when it comes to hydrogen generator safety: As the smallest gas molecule in the universe, hydrogen is particularly prone to leaking out of containment, both in storage and pipelines.5

The result is that hydrogen boiler and hydrogen generator safety can only be ensured with the implementation of reliable gas detection technologies.

Ensuring Hydrogen Generator Safety with the MK8 Pellistor

Identifying hydrogen leaks rapidly and reliably is of critical importance for hydrogen generator safety. Many different technologies are suitable for hydrogen gas detection – however, pellistor sensors provide the most direct route to identifying combustion hazards that impact hydrogen generator safety.

Pellistor sensors – also known as catalytic bead sensors – contain a catalyst pellet that causes flammable gases within the sensor to ignite at a much lower temperature than usual. When combustion occurs, the amount of heat produced is proportional to the concentration of flammable gases present. Pellistor detectors measure heat production and use this to accurately determine the concentration of flammable gases in the air, expressed as a percentage of the lower explosive limit (%LEL). When considering hydrogen generator safety, the key hazard is flammability: this means that pellistor sensors are the preferred detector type for ensuring hydrogen generator safety.

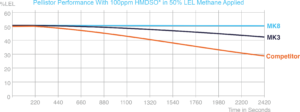

IGD’s MK8 is the world’s most advanced pellistor sensor and is ideally suited to hydrogen boiler and hydrogen generator safety applications. While other pellistor detectors are vulnerable to “poisoning,” a loss of sensitivity to the target gas caused by the presence of other gases and vapors, the MK8 is the most poison-resistant pellistor detector on the market.6 This ensures that the MK8 detector can reliably ensure hydrogen generator safety in all conditions.

The MK8 also offers extreme stability, with less than 2% LEL drift per year. This ensures a long operating lifetime and low cost of ownership, making the MK8 ideal for long-term hydrogen generator safety applications. On top of this, the MK8 operates perfectly over a wide temperature range and is unaffected by humidity – both important factors when considering hydrogen generator safety systems.

The MK8 pellistor detector is easy to install and provides digital data via 2-wire Sentinel+™ Addressable communication, ensuring easy integration into any hydrogen generator safety system. The sensor element itself can be easily replaced after its typical service life of 5 years. Please see our datasheet here for the MK8 Pellistor.

International Gas Detectors is a world-leading developer of gas detection technologies for hydrogen boiler, hydrogen fuel cell, hydrogen generator and a plethora of other hydrogen safety applications. To find out more about hydrogen generator safety and our MK8 detector, get in touch with IGD today.