Setting a New Standard in Flammable Gas Detection

International Gas Detectors Ltd have designed and released a new standard for flammable gas detection, the MK8 pellistor gas detector. The MK8 pellistor gas detector combines over 65 years of pellistor engineering with reliability and tested performance to provide clients with the most accurate, poison resistant pellistor based gas detector in the world. This advancement in pellistor gas detector design demonstrates IGD’s commitment, innovation and capability. Read our article below to find out how the MK8 is setting a new standard for flammable gas detection.

Extreme Resistance to Poisoning and inhibition

Pellistor based sensors all use a heated catalyst to combust flammable gas. The consequent temperature change can then be directly related to the gas concentration. Any such device based on catalysts will be susceptible to ‘poisoning’. Poisoning occurs where certain chemicals and compounds react with the surface of the catalyst and by their action reduce the response of the catalyst to the desired target gas. These chemicals and compounds fall into two groups. Poisoning agents act on the catalysts irreversibly, inhibitors are recoverable to some degree. Typical poisoning agents would be organic silicon compounds.

A poorly designed catalyst structure can loose over 90% of its response in a few minutes when exposed to a standard 10ppm poisoning agent (HMDSO) used in testing. Typical inhibitors where the poisoning effect is reversible could be halogen containing hydrocarbons or compounds containing sulphur.

IGD’s MK3 pellistor has been best-in-class for flammable gas detection for many years. Designed in the early 1980’s the MK3 has become a byword for performance and reliability under the harshest of conditions. At IGD we didn’t think it could be beaten but we were wrong and the MK8 has taken its crown.

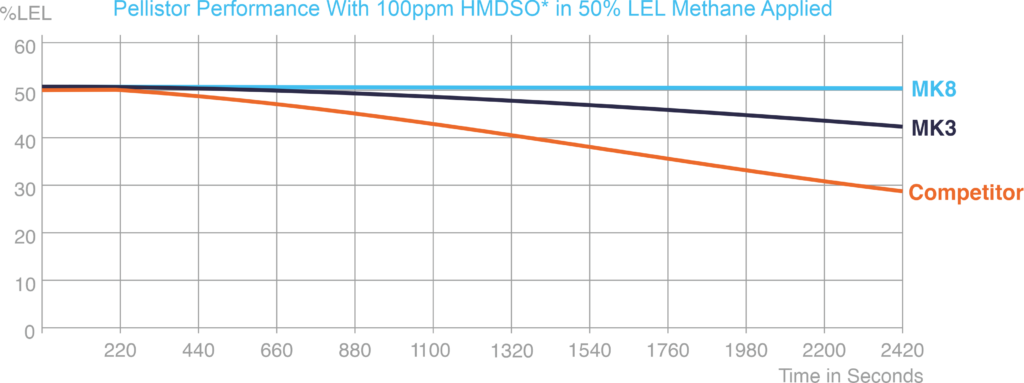

The MK8 pellistor gas detector shows extreme poison resistance to standard poisoning agents. The graph below shows the results from our standard poisoning test. The MK8 was put up against our older MK3 pellistor gas detector and our closest competitors pellistor. Industry standard tests only apply 10ppm poisoning agent for 40minutes.

However, IGD’s standard test requires 100ppm for 40minute to simulate real world conditions. As you can see from the graph the MK8 surpasses both our older MK3 and our competitors pellistor gas detectors continuing to respond reliably to flammable gas in the presence of a poisoning agent. Thus, setting a new standard for flammable gas detection.

Longer Life, Lower Cost of Ownership

Current industry pellistor gas detectors offer a 2-4 year operational lifetime which incurs ongoing cost of ownership to clients. Our new MK8 flammable gas detector has exceeded and set a new standard for pellistor gas detector lifetimes and reducing cost of ownership. The MK8 features the industries longest operational service life of 5 years plus. In addition the pellistor itself is a plug replaceable design. Now you don’t need to replace the complete stainless steel detector head and electronics. Just pop in a new sensor cartridge, calibrate and your up and running again.

The Ideal Technology for Hydrogen Gas Detection

As well as being an important industrial gas, hydrogen is becoming an increasingly important green fuel. Our hydrogen gas detection page discusses the hydrogen economy further and our detection solutions. However, the new MK8 pellistor gas detector enhances safety especially with the hydrogen economy. Providing clients with industry leading accuracy for flammable gas detection and designed for harsh conditions. This provides clients with the ultimate, cost effective, long life, yet reliable solution for detecting hydrogen gas. Available in the TOC-750X ATEX/IECEx zone 1 and 2 environments with IP68 rating, the 750S sampler, the 750 Safe area gas detector and our brand new 903-X5 dual sensor gas detector.

Engineer at Hydrogen fuel production facility

End Result – New Standard for Flammable Gas Detection

The MK8 Pellistor gas detector is feature rich and solves many problems the industry was currently facing with Pellistor type gas detectors. Extreme poison resistance and long term stability with less than 2% LEL drift per year combined with our leading digital addressable technology, the MK8 Pellistor gas detector is setting a new standard for flammable gas detection. Below is a list of key features that our MK8 provides clients:

- Extreme poison resistance exceeding international standards IEC EN 50194 and BS EN 60079-29-1 – for a high quality and reliable gas detector for longer

- Long term stability with less than 2% LEL drift per year – ensuring a higher accuracy of reading compared to the market standard

- Resistant to shock and vibration exceeding the requirements of BS EN 60079-29-1 – for applicability in almost any environment

- Only responds to flammable gases – reducing cross interference

- Operates over a wide temperature range and unaffected by humidity – for high quality flammable gas detection in continuously changing environments

- Calibrations for the largest range of flammable gases available on the market. (see our datasheet)

- Longest operational life in the industry

- True digital, addressable communication, utilising IGD’s Sentinel+ communication on the 750 series gas detectors and the 903-X5 – for gas detection on distances up to 1km, and 70% cost saving on your system installation

Pictured: TOC-750XD with the all new MK8 Pellistor gas detector for advanced flammable gas detection.

The MK8 Pellistor is available in the any of the 750 series gas detectors and the new 903-X5.

The 750 safe area is the ideal device for non ATEX rated areas. Its ABS design is extremely robust, offering a high level of chemical resistance and a unique labyrinth sensor design. This ensures that your sensor does not become contaminated and allows for application in a plethora of areas. The easy auto changeover sensor fronts provide seamless sensor changeover once they become end of life, reducing worker downtime.

Pictured: TOC-750 safe area addressable gas detector.

The 750X ATEX and IECEx rated gas detector is ideal for zones 1 and 2 and zones 21 and 22 dust environments. With this rating, the 750X is both weather and explosion proof, for reliable gas detection in turbulent and dangerous environments. The 750X is available both with and without a display, for maximum flexibility on your system. Furthermore, the 750X with a display (750XD) comes with a non-intrusive display, allowing for safe and easy detection in ATEX rated areas without a hot works permit.

The 750S is our aspirated gas detector, perfect for hard to access areas, clean rooms, and height restricted areas. With the 750S, bore holes can be fitted into walls outside of the rooms requiring gas detection, with pipes fitted through for effective sampling. Furthermore, the 750S features our patented piezo pump technology, with virtually no moving parts meaning it is easy to clean and virtually silent in operation without compromising on performance.

The new 903-X5 is the most versatile gas detector on the market, with dual detector capability for multiple gas detection at a single point. Similar to the 750X, the 903-X5 features a non-intrusive calibration feature utilising our magnetic wand technology. Furthermore, the 903-X5 features 5 port housing, allowing for application into an addressable or analogue system with ease, or alternatively can be used as a standalone device.

Pictured: the TOC-903-X5 dual sensor gas transmitter

Contact Our Team for the new MK8 Pellistor Gas Detector

Are you interested in our MK8 flammable gas detector? Or looking to implement this new standard in flammable gas detection as part of your gas detection system? Contact our team of gas detection experts today. Based in the UK and with one of the largest global distributor network in the industry we can provide full support from site surveys, project support, supply, and quotation. No project is too small or too large for IGD and our global distributor network.