Addressable is often seen as being complex; this is a common myth and does not match up to the simplicity of the system and plethora of benefits that addressable gas detectors can offer. This article explores these features and benefits of addressable gas detection, in particular with IGD, demonstrating how we can enhance your safety with detectably better addressable gas detectors. Read below to find out more.

PID Gas Monitors for Climavent

One of our most recent projects includes the implementation of our PID Gas Monitors for a fume extraction company known as Climavent. Their client required these PID detectors in their fume extraction systems to check the state of the carbon filters. Issues with current devices led to the widely successful implementation of IGD’s PID gas monitors, improving the safety of their team, and opening the doors for further opportunities to enhance Climavents gas safety. Read on below for more detail about how the Climavent team became detectably better in their gas safety.

How Sputtering and Humidity Affects your PID Sensor

As a lot of our readers may have seen in our PID and VOC articles, we frequently mention the terms ‘sputtering’ and ‘humidity’ and their effects on a PID sensor. But what does sputtering mean? And how exactly do these have a negative effect on the performance of a PID? This article aims to answer these questions, detailing these issues and how IGD has managed to negate them from our PID sensors.

Why is Hydrogen Gas Detection Becoming More Important?

Hydrogen (H2) has become a popular choice for use in the industrial sector in recent decades, but the demand for it has increased and looks set to continue. With high demand for hydrogen comes a need for more reliable and readily available hydrogen gas detection systems. In this post, we will discuss how hydrogen gas is used, the importance of hydrogen gas detection and what options are available.

What are VOC Gases?

What are VOC gases? Where are they found? How can I mitigate the Hazards of VOC’s? These are all vital to consider if working around VOC gases, as VOCs are extremely hazardous gases causing a plethora of health issues. This article answers all of these important questions, as well as suggesting detectably better gas detection equipment in order to help mitigate the presence of VOC gases. Read on to find out more.

How Do We Monitor VOCs and Why Do We Use VOC Detectors?

VOC’s are extremely common and can be from surprising sources. Each VOC comes with its own exposure hazards and reasons these need to be monitored, these can be found by accessing each materials Material Safety Data Sheet (MSDS). But how are these monitored? And why do we monitor these gases? These questions will be answered in this article to help provide a basic understanding of VOC gases and the dangers.

Why are O2 monitors required for MRI units?

MRI units are not commonly thought of when talking about gas safety, however these areas can quickly become dangerous when leaks occur. Understanding the dangers of MRI units as well as the gases used within them are vital to understanding why O2 monitors are required in these areas. This article covers all of the essential information in understanding this. Including the gases encountered in these areas to providing you details of IGD’s detectably better solution in O2 monitors.

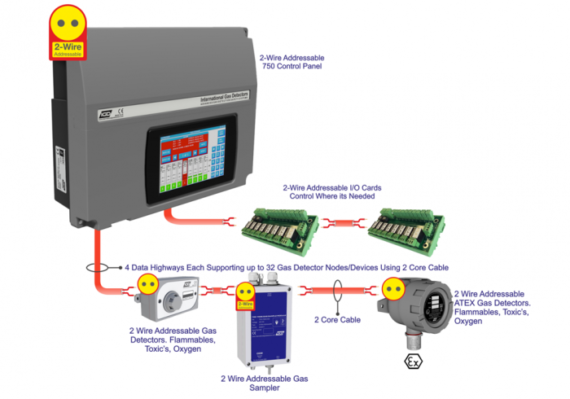

New Advancements In Gas Detection Technology

IGD launches its new Advanced 2-Wire gas detection Technology. Devices are networked using 2 core cable offering major benefits to specifiers, installers and end users. 2 Core cable minimises install