Recently one of our directors got involved in a discussion on the Gas Detection professionals LinkedIn Group regarding a member’s concern for sample points, and felt the comment was worthy for further explanation.

The concern was should you utilise detectors with sample pumps?

In general terms, the answer to this question is no. Anything that comes between the detector and the hazard introduces the potential for unreliability and consequent detection errors. At International Gas Detectors, we would always try to deploy diffusion based sensors directly into the area of concern. This is by far the most reliable method. In some instances, this is not possible and at that point we consider the use of sampling gas detectors.

IGD’s Concern:

Currently we are fitting out six Gene Therapy Modules for a client. These are highly sterile environments which are regularly fumigated. Normal diffusion based gas detectors could not be used. The client wanted to minimise equipment in the modules to limit the potential for bacterial traps. Extracting a sample for gas detection was the only solution.

Many sampling gas detection systems sequentially sample to a common detector. On systems with many detection points this approach can lead to long cycle times. Take the example of a system with 10 sample points and a 2-minute sample time at each point. The cycle time is 20 minutes meaning 9 out of 10 ports won’t be sampled for 20 minutes.

The Solution:

IGD produce both addressable sample pumps and addressable 4 port samplers. This negates the problem of long cycle times. If the application is critical then use a point sampler where the pump/detector is dedicated to just one sample point. In less critical applications, a 4 way addressable sampler only ever has a maximum of 4 ports to sample around, minimising dead time.

In addition, IGD’s Piezo pump technology has virtually no moving parts. Many sampling systems have a multiplicity of pumps, filters, valves etc as part of their make up all with associated seals and wear parts. IGD’s samplers use piezo pump technology, no seals, wear parts, valves or diaphragms to maintain. IGD’s samplers are virtually maintenance free and self-monitoring.

The samplers employed by IGD extract their sample through IGD’s unique gas sample port. This is fitted through the wall minimising the impact inside the clean room. The sample port is available with a luer fitting allowing standard anti-bacterial filters to be fitted in normal operation. In addition, this allows the ports to be ‘capped off’ during fumigation.

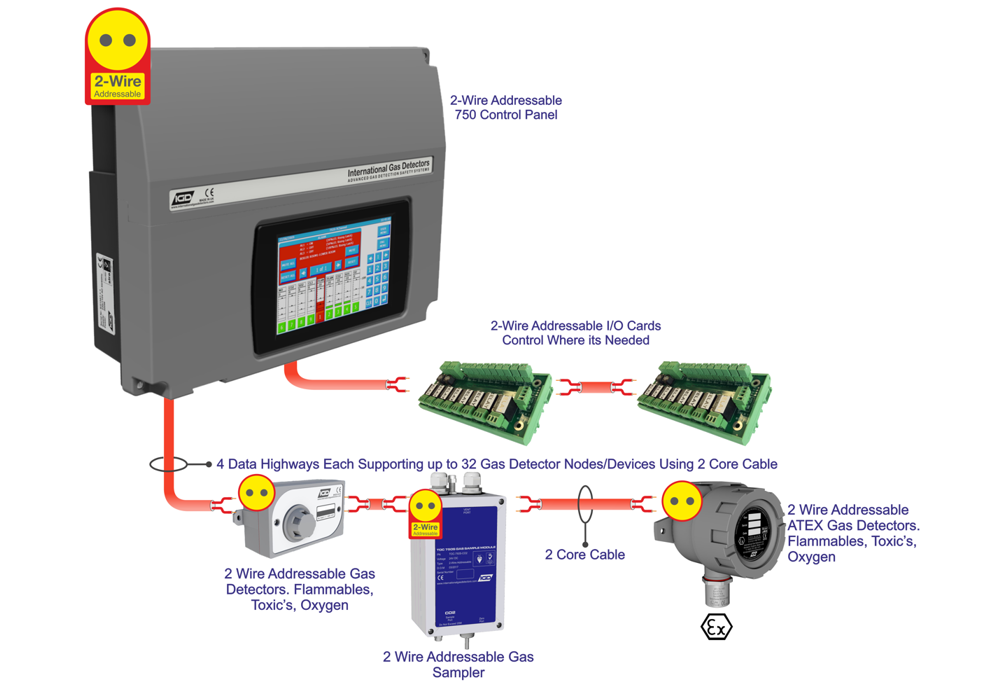

In this application IGD located all sampler modules local to the sample points. 60 samplers were fitted all networked using our Sentinel+ addressable highway technology. Each sampler has very short sample lines, local flow monitoring and the capability to self-zero or in the case of Oxygen detection, self-calibrate.

‘The system has reduced cost compared to sequential samplers’

One of the biggest wins for the client; the system has reduced cost compared to sequential samplers and utilising IGD’s novel Piezo samplers there is no conventional sample pump, no solenoid, no moving parts with equipment providing over a 5 year lifetime.