Volatile organic compounds (VOCs) are very widely used in industry and represent a significant hazard to human health. In this blog post, we take a look at what VOCs are, their role in industry, and the importance of VOC detectors for maintaining industrial hygiene.

What is a VOC?

To a chemist, an organic compound is any chemical that contains one or many carbon-hydrogen bonds. This broad class of chemical compound is so-named because it constitutes many of the molecules on which life is based – including DNA, proteins, and sugars.

A compound is considered volatile if it has a high vapor pressure at room temperature. If a compound has a high vapor pressure, it has a high propensity to evaporate and diffuse through the air around it.

So, a volatile organic compound, or VOC, is any compound containing carbon-hydrogen bonds that are also prone to evaporation. Naturally, this class of chemical compounds is quite broad and has many relatively harmless chemicals produced by healthy plants and animals.1,2

However, many VOCs produced or used in industry present serious health risks. Common examples of harmful industrial VOCs include benzene, ethyl-benzene, styrene, toluene, and xylenes. In common usage, the term “VOCs” is a convenient way of grouping together these various compounds. Similarities in chemistry mean that VOC detectors are capable of measuring levels of many of these compounds as a group.

VOC Detectors Minimize Health Risks

Exposure to VOCs in varying concentrations can have a variety of acute and chronic health effects. The most common symptoms of exposure are acute and include irritation of the eyes and/or throat, dizziness, nausea, and in rare cases, loss of consciousness or death.

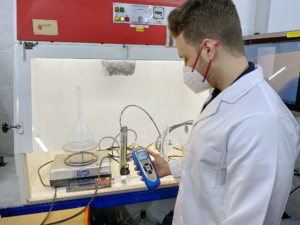

the NEO PID being used for Fume Cupboard gas detection

The chronic effects of long-term VOC exposure can be serious. These include damage to internal organs like the liver and kidneys, disruption to the endocrine system and central nervous system, and cancer.3 This is why VOC detectors are necessary for the protection of people exposed in industrial settings.

Occurence of VOCs in Industry

VOCs occur in many forms in modern industry. They are broadly used as industrial solvents, fuel oxygenates, and refrigerants; and also crop up in the production of paints, pharmaceuticals, and hydraulic fluids.4

Due to their potential harmfulness and their common occurrence in virtually all industrial sectors, VOCs are of major concern to industrial hygiene and indoor air quality. As a result, the use and production of VOCs are regulated by law, especially in indoor environments where concentrations can reach much higher levels. VOC detectors are a critical part of industrial hygiene.

VOC detectors are designed in a variety of forms that can be tailored to different applications depending on the specific needs of where the technology will be utilized.

Fixed VOC Detectors

Fixed VOC monitors are typically deployed wherever there is a specific VOC hazard present. For example, fixed VOC monitors may be installed in a factory where a certain processing step uses volatile organic solvents. Larger facilities often opt to install sitewide networked addressable VOC detectors, while small system, VOC detectors offer a good solution for smaller areas.

VOC detectors utilise Photoionisation Detection (PID), which is key for detecting low concentrations of volatile organic compounds. International Gas Detectors Ltd. (IGD) provides a range of PID detectors, including the TOC-750X ATEX Addressable PID VOC Detector, TOC-750 Addressable PID VOC Detector, and the TOC-750S Sampling PID Detector.5 These devices are versatile, overcoming traditional challenges to sensors like the negative effects of humidity and sputtering. Our new standard for VOC detection provides accurate detection of VOC gases and boasts a long lamp life of between 15,000-30,000 hours using a non-electrode UV lamp, this is a 50-200% increase compared to current alternatives on the market.

Portable VOC Detectors

Portable VOC detectors are carried by individual personnel and automatically monitor VOC levels in their surroundings as they move from place to place. They are ideal for users moving between sites, entering confined spaces or for the long term exposure monitoring. mPowers POLI from IGD offers ideal VOC detection for personal protection, providing the most stable and linear personal VOC detection on the market. IGD also supplies one of the most accurate and advanced portable monitors called the PID NEO. This device can detect low levels at parts ber billion all the way up to 15,000 ppm levels; this outstanding sensitivity makes it one of the most versatile products applicable to a diverse set of conditions and uses.6

Portable VOC detectors are carried by individual personnel and automatically monitor VOC levels in their surroundings as they move from place to place. They are ideal for users moving between sites, entering confined spaces or for the long term exposure monitoring. mPowers POLI from IGD offers ideal VOC detection for personal protection, providing the most stable and linear personal VOC detection on the market. IGD also supplies one of the most accurate and advanced portable monitors called the PID NEO. This device can detect low levels at parts ber billion all the way up to 15,000 ppm levels; this outstanding sensitivity makes it one of the most versatile products applicable to a diverse set of conditions and uses.6

The Experts in VOC Detection

IGD has been designing and manufacturing gas detectors for over 100 years. To find out more about our VOC detectors and other gas detection solutions, get in touch with us today.

References:

- Shirasu, M. & Touhara, K. The scent of disease: volatile organic compounds of the human body related to disease and disorder. J Biochem 150, 257–266 (2011).

- Broza, Y. Y., Zuri, L. & Haick, H. Combined Volatolomics for Monitoring of Human Body Chemistry. Sci Rep 4, 4611 (2014).

- US EPA, O. Volatile Organic Compounds’ Impact on Indoor Air Quality.

- US EPA, O. What are volatile organic compounds (VOCs)? https://www.epa.gov/indoor-air-quality-iaq/what-are-volatile-organic-compounds-vocs (2019).

- VOC and Benzene Detection. (2021, November 3). IGD. https://www.internationalgasdetectors.com/voc-benzene-detection/

- Portable VOC Gas Detector – PID NEO. (2022, January 27). IGD. https://www.internationalgasdetectors.com/product/portable-voc-gas-detector-pid-neo/