Some industrial environments are more dangerous than others.

Flammable gases, confined spaces and exposure to aggressive chemicals present a serious threat to employees in many industries. The key regulations that provide crucial guidance on the management of these environments are ATEX and DSEAR, and the only way to comply with these regulations is with an appropriate gas detection system.

What is ATEX?

An ATEX-rated area refers to any zone where there is a risk of an explosive atmosphere due to the presence of flammable gases, vapours, or dust. These areas are ruled by stringent regulations to ensure safety, primarily through the use of certified equipment designed to prevent fires. Understanding the different ATEX zones and their specific requirements is crucial for maintaining safety.

What is DSEAR?

The Dangerous Substances and Explosive Atmospheres Regulations mandate the evaluation and management of the potential risk to personnel from fires or explosions caused by hazardous substances in the workplace. You are required to mitigate or minimise these risks to the extent that is possible. DSEAR regulations mandate that flammable atmospheres must be avoided by ensuring that flammable gas concentrations do not exceed 25% of their Lower Explosive Limit (LEL).

What Does ATEX Stand For?

ATEX comes from the description of the hazardous materials in question. it comes from the French — “Appareils destinés à être utilisés en ATmosphères EXplosives.” The translation into English reads, “Devices intended for use in explosive atmospheres.”

What are ATEX Zones?

ATEX zones classify hazardous areas based on the frequency and duration of explosive atmospheres. This helps to determine the type of equipment and safety measures required in each zone. Let’s explore the different zones:

Gas Hazards

- Zone 0: This is the highest-risk area where an explosive atmosphere is present continuously, or for extended periods. Equipment used here must provide the highest level of protection. Zone 0 is the least common ATEX rating.

- Zone 1: In Zone 1, an explosive atmosphere is likely to occur during normal operations. While the risk is slightly lower than in Zone 0, the need for high-quality, reliable gas detection systems remains critical.

- Zone 2: This zone represents areas where an explosive atmosphere is not likely to occur during normal operation, but if it does, it will only persist for a short period. Although the risk is lower, effective gas detection systems are still an essential preventive measure.

Dust Hazards

- Zone 20: An explosive atmosphere in the form of combustible dust is present continuously or for extended periods.

- Zone 21: An explosive atmosphere in the form of combustible dust is likely to occur occasionally in normal operation.

- Zone 22: An explosive atmosphere in the form of a cloud of combustible dust is not likely to occur, and if it does occur will persist only for a short period.

Why is Gas Detection Essential in ATEX-Rated Applications?

The presence of explosive atmospheres in ATEX-rated areas necessitates robust safety measures, and gas detection systems sit at the heart of these measures. Here’s why:

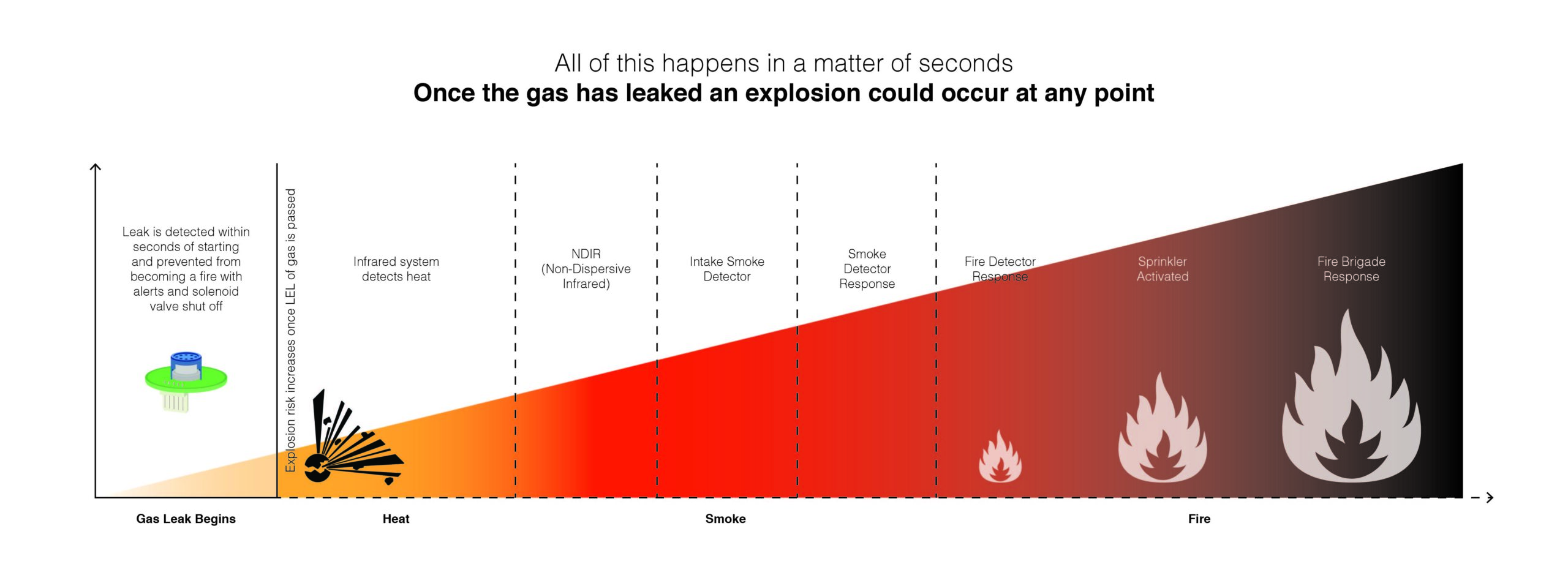

- Prevention of Explosions – The primary function of gas detection is to identify the presence of flammable gases or vapours before they reach a dangerous concentration. By detecting these gases early, we can prevent conditions that might lead to an explosion. Unlike a fire safety system, a gas detection system is a preventive measure. preventive systems stop fires and explosions long before they’re able to break out.

- Regulatory Compliance – ATEX and DSEAR regulations are stringent, and non-compliance can lead to severe penalties and an increased risk of accidents. IGD can provide bespoke gas detection systems to ensure that your application and operation meet regulatory standards which safeguards both personnel and assets. You can find out more about the laws surrounding gas detection in our latest blog here.

- Protection of Personnel – The safety of the workforce is always the top priority and the more dangerous an environment, the more care must be taken in protecting your personnel. IGD gas detection systems can provide real-time monitoring, tiered alarms, SMS and email alerts, detailed data downloads, remote monitoring and pre-entry warnings, ensuring that workers are aware of any potential dangers as early as possible.

ATEX Solutions from IGD

IGD has been developing gas detection technology for longer than any other company in the world. Over 100 years in operation, we have pioneered both Safe Area and ATEX gas detection solutions which can be integrated into our groundbreaking 2-Wire Addressable gas detection systems to save you up to 70% on your installation.

Our ATEX-certified detectors come in a custom housing making them suitable for ATEX zones 1&2 (gas) and zones 21&22 (dust):

TOC-750X ATEX Gas Detector

- Plug-and-Play sensors automatically update the system to monitor for different gas types and ranges

- Sensor options for over 400 gases and vapours

- IP 65 weatherproof

- Display and non-display options with non-intrusive calibration

- Sentinel+TM addressable digital communication protocol

- Connect to other devices via a single cable

TOC-903-X5 Dual Gas Detector-Transmitter

- Non-intrusive one-man calibration via magnetic wand

- IGD leading long-life Plug-and-Play sensor technology

- Dual sensors monitors mean you can monitor two different gases simultaneously

- 5 Port Housing

- 2x 4-20mA outputs, 3x Relay outputs, 1×2-Wire Addressable output

- Sensor options for over 300 gases.

- Illuminated colour-changing display for at-a-glance status readings

- IP 65

- Can be used as a detector in an IGD system, or as a standalone detector-transmitter

Check out our article on “The Top 10 Features of The TOC-903-X5”.

Getting gas detection isn't a choice. Who you get it from is.

Gas detection is not just a regulatory requirement, it’s a critical component of a comprehensive safety strategy. Whether you’re in the oil and gas sector, chemical manufacturing or any industry where explosive atmospheres are a risk, ensuring that your facilities are equipped with the right gas detection system is essential. At IGD we understand the complexities of ATEX-rated environments. Our range of gas detection products is certified to meet the highest safety standards, offering unparalleled protection for your operations. With our century of operation and 10-year warranty on electronics, you can rely on IGD to provide ATEX-rated, fully scalable gas detection solutions for any application. IGD engineers and consultants are COMPEx trained and well-equipped to fight these gas hazards by providing planning, installation, onsite support and advice on your setup.

Contact Us

Get in touch with us today to find out how we can provide you with the perfect ATEX-rated gas detection solution. Check out our latest case study “The TOC-903-X5 steals the show at ACHEMA 2024” or take a deep dive into the laws and regulations surrounding gas detection here.

Alternatively, check out our entire range of ATEX and Safe Area Gas Detectors here.