Why are O2 monitors required for MRI units?

MRI units are not commonly thought of when talking about gas safety, however these areas can quickly become dangerous when leaks occur. Understanding the dangers of MRI units as well as the gases used within them are vital to understanding why O2 monitors are required in these areas. This article covers all of the essential information in understanding this. Including the gases encountered in these areas to providing you details of IGD’s detectably better solution in O2 monitors.

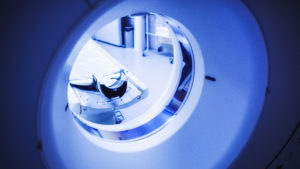

Magnetic Resonance Imaging (MRI) are scans used by medical professionals allowing them to look inside of a patient’s body without using harmful radiation or X-rays. These units do this by utilising large magnets and radio waves. Each of these scanners are installed in an empty, closed room ensuring the safety of the other personnel in the area as the magnet is extremely strong.

Pictured: MRI scanner

What gases are used in the MRI process?

MRI machines create an enormous magnetic field, thus it uses a lot of energy. In order to keep the energy usage level high, the temperature of the wires needs to be kept low to maximise its conductivity. In order to do this, the wires are continually doused with liquid helium, as the fluid temperature is -269.1°C making it ideal for this usage. However, helium becomes gaseous at temperatures above -269°C so it can easily leak in hospital and medical environments.

Why does Helium need to be monitored using an O2 Monitor?

Helium can quickly become a hazard in these environments due to the rate at which it will lower the oxygen levels in a room. This is because if an MRI machine begins to leak Helium it will begin to replace the lost Helium, resulting in a constant leak of helium gas. An MRI machine utilises 1700 litres of helium and just one litre will fill 26.6 cubic feet of a room, thus it can quickly become an oxygen depleted environment. Oxygen is constantly in the atmosphere, at a level of 20.9%, and it is essential to human survival. Even drops in O2 as little as 2% can be extremely dangerous to the personnel in these environments, with depletion causing issues such as asphyxiation and death rapidly. Thus, using an O2 monitor can be lifesaving in environments with potential to deplete, such as an MRI unit. Finding a suitable O2 monitor is vital when implementing into these environments, as a dependable and reliable device is best to ensure your safety.

Detectably better O2 monitor solutions

The most effective solution for O2 detection is the TOC-750 safe area O2 monitor paired with the 635 control panel, both from IGD. The 750 is perfect for MRI rooms, providing an equally effective alternative to ATEX protection. This device can be implemented for a dramatically reduced cost in comparison to analogue and other addressable units, in addition to being a higher security and higher reliability.

The 750 O2 monitor from IGD boasts one of the longest lives on the market, with a 5 + year lifetime, thus there is no need for short term, expensive replacements. In addition to this, the O2 sensor utilises a solid polymer-based technology rather than a lead based. This means that the O2 monitor will not consume itself and become ineffective, which is a common issue with current alternatives. This technology by IGD ensures maximum efficiency in operation. Both enrichment and depletion detection are available on the IGD O2 monitor, thus any changes in your atmosphere are known about.

Pictured: The 750 safe area O2 monitor from IGD

The 635 controller is the perfect addition to this system, with the ability to monitor between 1 and 32 detectors, being flexible for almost any system size. This is ideal for hospitals with multiple MRI units and multiple O2 monitors, ensuring easy system tracking from one panel. This panel comes equipped with a built-in slam switch, designed for easy access and reducing the need for additional slam switches. Thus, saving time, cost and less errors on commissioning.

Pictured: the TOCSIN 635 control panel

These systems can be equipped with a wide range of accessories, suitable to your requirements. We also manufacture detector options for remote sampling if the MRI unit is hard to access. This ensures little disruption when servicing the monitoring. All this capability and cost saving, coupled with our leading 10-year warranty* ensures we provide clients with the detectably better O2 monitor solution.

Contact us

Contact our team of experts here to find out more about this detectably better O2 monitor and our support options available. Alternatively visit the product page on our website where you can learn more about the TOC-750 addressable detector and speak to one of industry leaders on live chat.