Ultimate Protection for a Fraction of the Cost

The Power of 2-Wire Addressable Gas Detection

Gas detection is a vital part of site safety in most industries. Implementing a gas detection system is the only way of detecting a gas leak and adhering to relevant regulations, so getting gas detection isn’t a choice, but who you get it from is.

However, if you don’t have an IGD 2-Wire Addressable gas detection system, you’re probably paying too much for your gas detection.

IGD has been at the forefront of the gas detection industry for over 100 years. Since our incorporation, we’ve been committed to two things: constant technological innovation and the promotion of gas safety education and today’s lesson is a simple, but valuable one:

Gas detection can be expensive, but it doesn't have to be.

Analogue Gas Detection

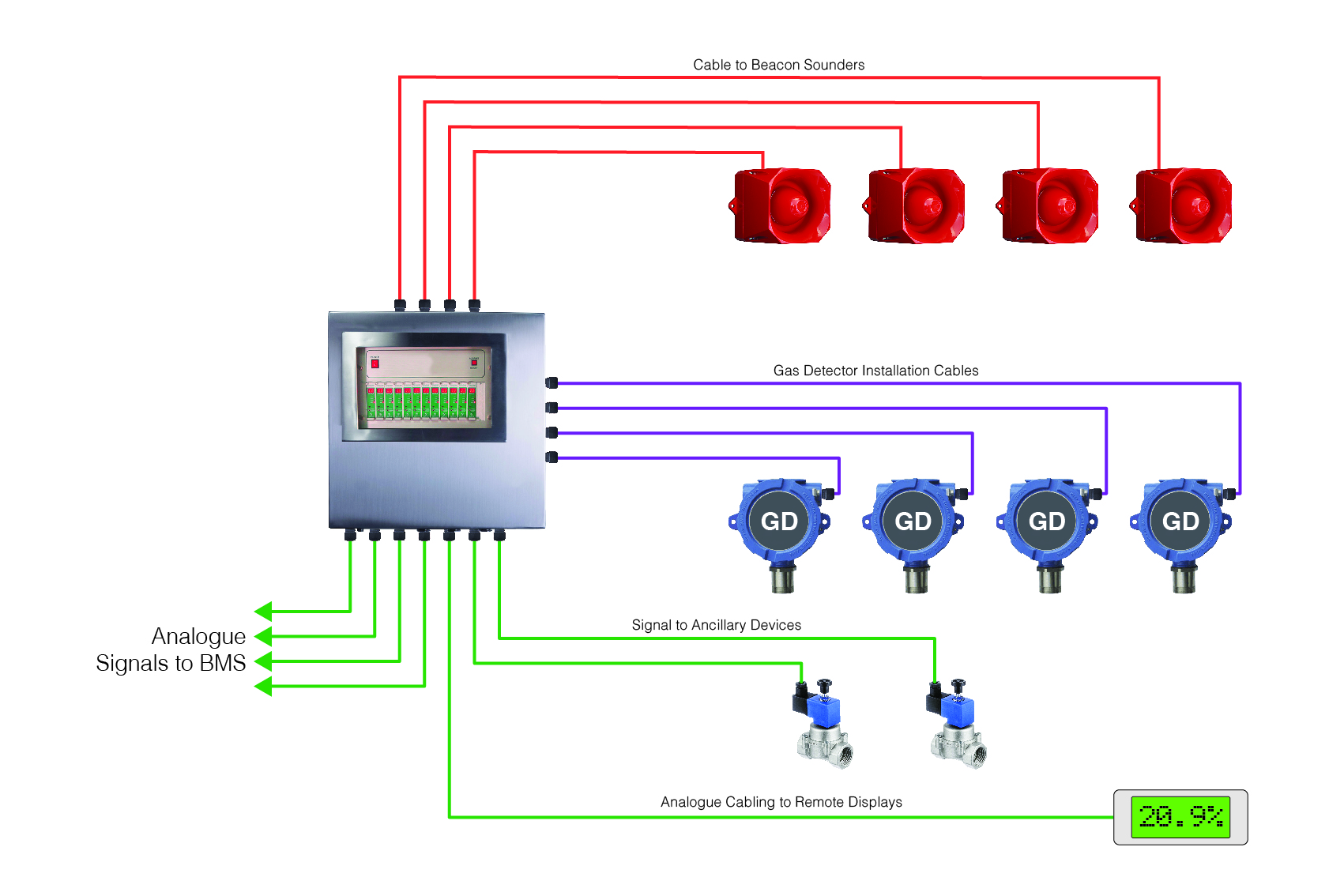

Analogue systems were the primary means of providing gas detection for decades, but in the 90s IGD changed the game. We invented addressable gas detection, which immediately highlighted all of the limitations of an analogue system. The diagram below outlines a typical analogue system:

As you can see, every element of an analogue system must be wired back to the central control panel, necessitating lots of wiring. As the application in question grows, wiring requirements increase exponentially and in the largest applications, wiring costs can make up a huge percentage of the overall system cost. But most of that wiring is a surplus to requirement.

Analogue systems aren’t pre-calibrated which means that every addition to a system will require setup and calibration. Their system cause and effect setup is inflexible limiting automated responses. They’re prone to accuracy errors and susceptible to human error during the installation and maintenance process. This, plus the additional time needed to install unnecessary wiring, will lead to additional installation and maintenance costs. We live in a data-driven world, and when it comes to life safety systems data is important. However, analogue systems are incredibly limited in terms of the kind of data they can provide. Funnily enough, addressable systems, address all of these issues.

Addressable Gas Detection

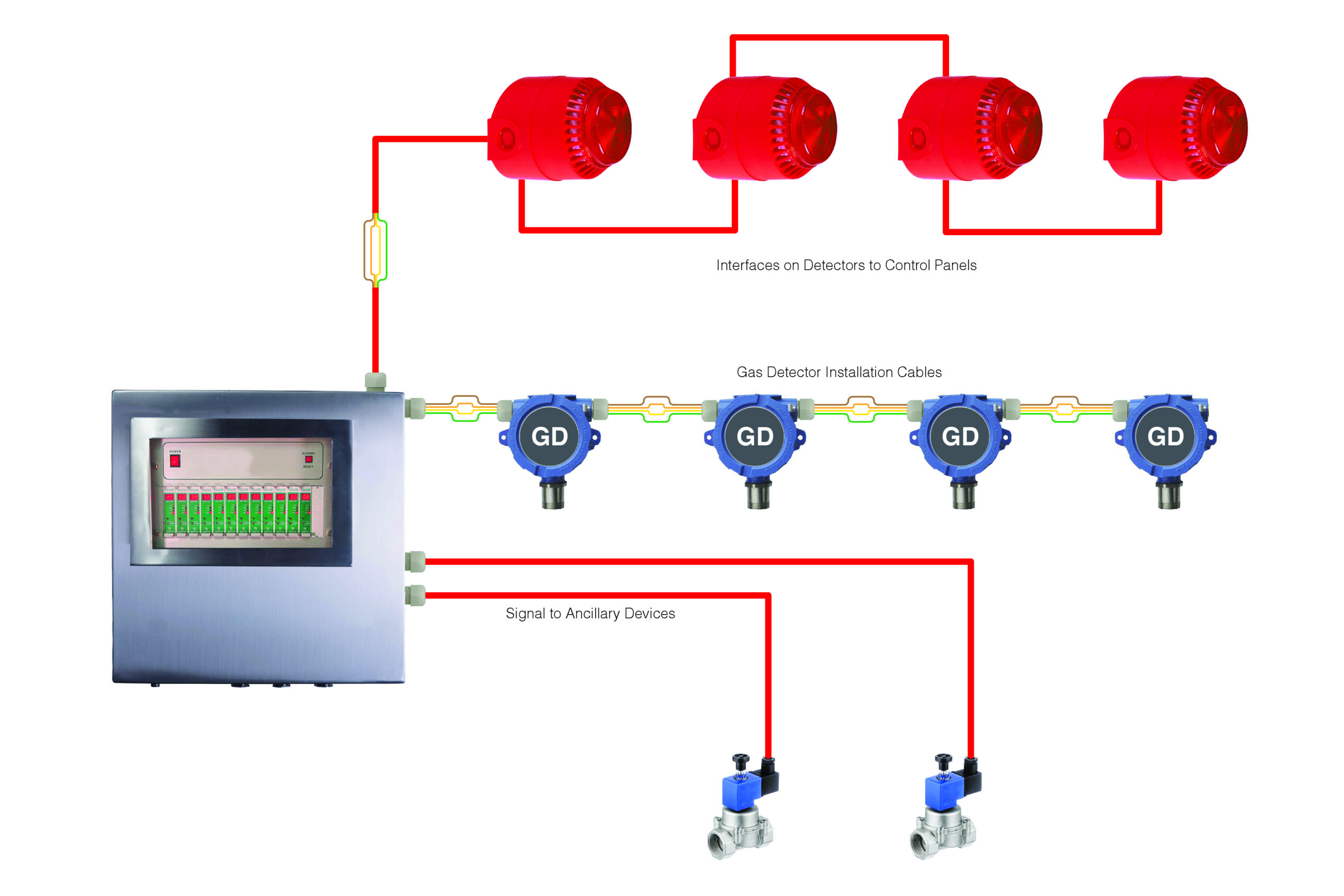

We invented Addressable gas detection to provide a faster, more reliable, more accurate, model for gas detection. A model that offered superior protection for less money. The key to the system is the ability to link detectors and devices in series on a single cable run from a controller or control panel slashing wiring costs in the process. Every connection point in a system’s wiring increases the room for error, so having fewer connection points makes the system more reliable, far safer, and way easier to install and service. Below is an image of the typical 4-wire addressable gas detection system. The rest of the industry still utilises systems with 4 or more wires. Not only does that still involve a lot of unnecessary wiring costs but it also presents issues with installation. having 4 or more polarity-dependent wires running between each component presents at least 15 opportunities to install the system incorrectly. At IGD we recognise that the key to improving safety is limiting the potential for human error, so we knew we could do better.

2-Wire Addressable Gas Detection – An IGD exclusive.

An addressable system accommodates detailed data handling. In the event of a gas leak, analogue systems could only really tell you that there was an issue. Addressable systems can pinpoint the location of an issue on even the most complex system, provide clear comprehensive data on the issue, and interface with the entire safety system to provide a range of automated responses.

Addressable gas detection marked a turning point in the industry, so its widespread market adoption came as no surprise. But we’ve come a long way since then and we’re now on our third generation of addressable technology; our fastest, most accurate and most efficient version to date that provided the answer to a simple question:

Could we cut the wiring requirements in half – again?

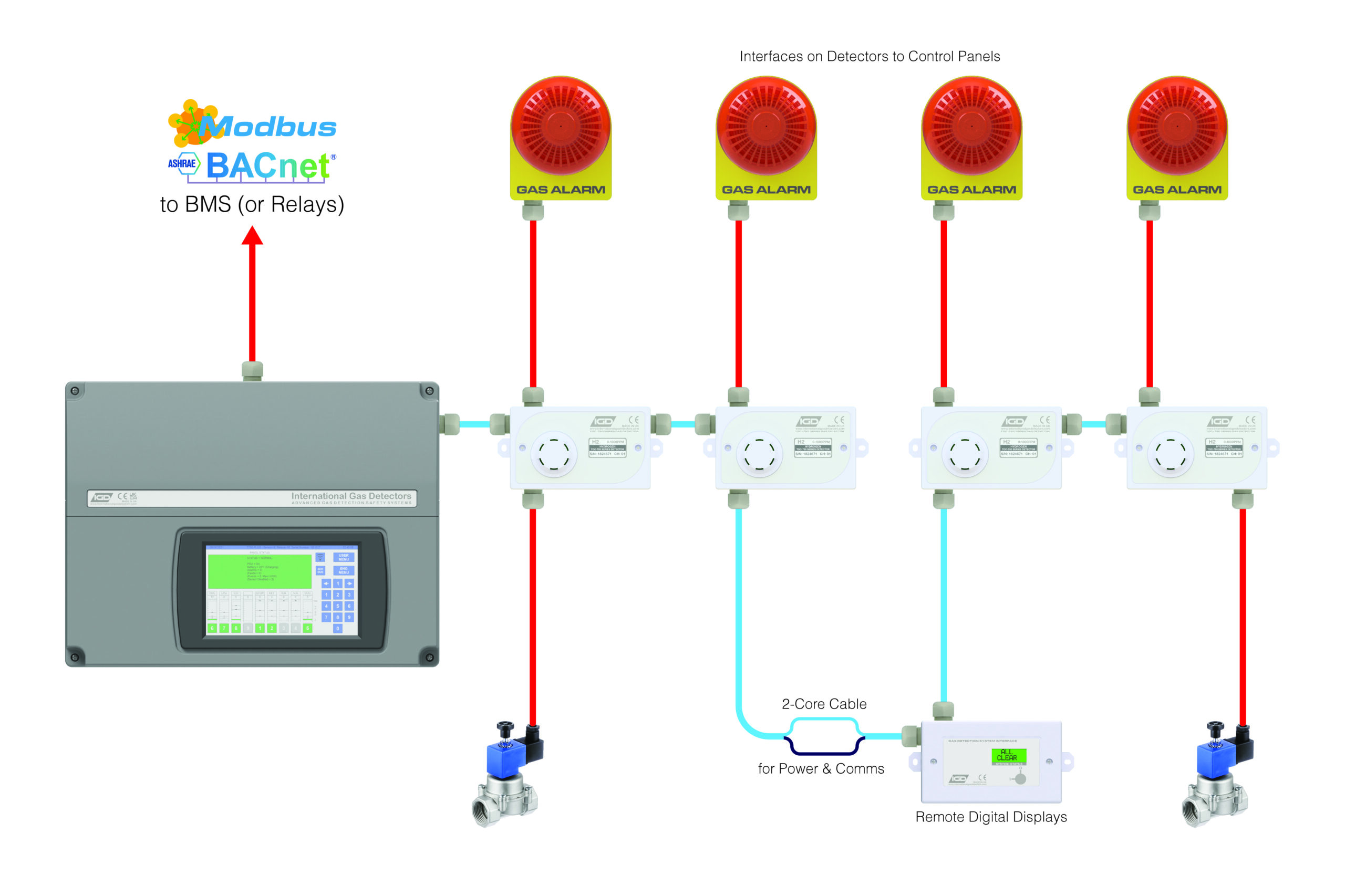

2-Wire Addressable technology is power and communication on a single 2-core cable. Simple, safe, swift. Everyone else uses at least 4 cables to run their systems; by doing a better job with just 2 we can offer ultimate protection for a fraction of the cost.

Again, you can link devices in series, and you can even repurpose your existing wiring to provide further installation cost savings. Using a single 2-core cable further reduces wiring costs and boosts reliability by minimising connection points. Polarity-independent wiring simplifies installation and maintenance. Our systems are truly scalable and backed by our Sentinel+TM software, which provides enhanced readings, targeted alerts, automatic sensor re-calibration, and full event logs.

Our 2-Wire Addressable gas detection systems feature built-in WiFi for full event monitoring, data downloads, and intuitive system interfacing for maintenance. Our optional Remote monitoring lets you monitor your gas detection system from anywhere via mobile, laptop, or tablet. You can perform cloud-based data acquisitions, receive SMS & email alerts for alarms and faults, and even reset the system remotely.

And that is why you’re paying too much for your gas detection.

Contact the team at IGD today and take advantage of the fastest, most reliable coverage for less. Take a look at our article on the laws and regulations surrounding gas detection, or check out our 2-Wire Addressable-powered, SafePark Car park gas detection range in action at The National Theatre in our latest case study.