Present in gasoline and crude oils, a leak of Benzene can happen in a large number of industries. Due to the carcinogenic, volatile nature of this gas, it is important to monitor this wherever it is likely to be present. Benzene gas detectors are the perfect way to keep personnel safe when working in close proximity with this gas, and this article details the ideal solutions to handle this. This article also discusses where Benzene may be found and the dangers of it, helping you understand why you want to have a Benzene gas detector.

The Dangers of Benzene

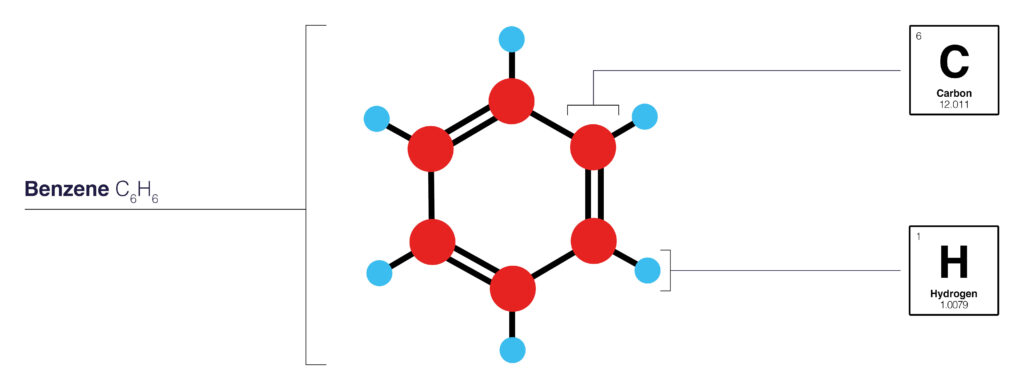

Created on 6 carbon atoms and 6 hydrogen atoms, Benzene is a colourless or light-yellow liquid at room temperature. This however can evaporate into the air very quickly and sink into low lying areas due to its vapours being heavier than air. And with the STEL of Benzene is as low as 5ppm, hazards can become a high potential. This is ultimately due to the carcinogenic nature of the compound, in addition to causing cardiovascular issues at a very low level. Both the World Health Organisation (WHO) (2010) and the American Petroleum Institute (API) (1948) both believe that there is no safe level of exposure to Benzene. Therefore, limiting exposure with a Benzene gas detector wherever possible is vital. But which applications require one of these devices?

Where Would you Need a Benzene Gas Detector?

Benzene gas could potentially be found in a wide range of industries, with most being environmental related applications as it is found in crude oil and gasoline. For example, Benzene gas detectors would be found in industries including Petrochemical, Refineries and Oil rigs due to Benzene gas potentially being released from the drilling and processing of crude oil. This could easily fill confined spaces quickly, especially on an oil rig, thus could endanger all in the proximity if not identified with a Benzene gas detector.

This Hydrocarbon is also naturally occurring from forest fires and volcanoes due to it being highly flammable and naturally occurring. Benzene may also be found in accidental situations such as oil spills or improper disposal of waste. Thus, a benzene gas detector would be found in these applications as firefighting or hazmat teams would be required to handle these materials on clean ups. One of these devices would be the most effective way to mitigate the risk of Benzene exposure. Other applications in need of a benzene gas detector could include soil remediation, thus construction teams would utilise this tool.

Benzene gas could also occur in man made applications, such as the manufacturing industry. Chemical and material manufacturing utilise benzene in the process of creating their products, such as when creating a more complex structure for some chemicals. Consequently, Benzene gas detectors would be implemented into storerooms for the Benzene compound. Due to the possibility of leaks, it would be essential to implement this to keep personnel safe.

Overall, there are a wide range of industries requiring a Benzene gas detector, but what benzene monitors are the most effective on the market?

Detectably Better Benzene Gas Detectors

IGD offer a wide range of detectably better benzene gas detectors, with a wide range of options to suit you and your industry.

The NEO Portable Benzene Monitor

Through our partnership with mPower, IGD can offer the lightest, smallest and most stable portable Benzene gas detector on the market. The NEO benzene monitor provides a battery life of up to 24hrs on one charge, even when connected to the app via Bluetooth. This high battery life ensures your NEO never runs out on a job. With the fastest response time on the market and huge datalogging capabilities, the NEO Benzene gas detector is perfect for applications including industrial hygiene, oil and gas and process. The NEO benzene offers faster sampling time than leading competing products, which is essential in refinery turnaround where every minute counts. This device is built with the user in mind; being able to withstand high concentrations of interfering compounds than competing products. Thus, your benzene gas detector tubing lasts longer.

IGD also manufacture our own range of fixed PID detectors. These can be used to sense Benzene in all of our fixed products, from safe area to ATEX as well as a sampling detector. Perfect for use in storage areas and the process industry.

The TOC-903-X5

The TOC-903-X5 is our latest series of our standalone gas detectors. These can be easily integrated into any IGD analogue or addressable system, making it the most versatile gas transmitter available on the market. The 903-X5 can easily be used as a benzene gas detector in any ATEX application as its approved to zones 1 and 2 explosive atmospheres and zone 21 and 22 dust atmospheres. And due to its dual gas sensing capabilities, this benzene gas detector can also detect any other gas from our range of 400 gases and vapours sensors. Making this the ideal addition to your oil and gas application.

The 750 Series

Our 750 series of gas detectors feature our outstanding 2 wire addressable technology, saving up to 70% on installation costs compared to the market average. These devices feature all of the benefits of a standalone system on our technologically advanced Sentinel+™ systems. Allowing for a 70% cost reduction on installation whilst increasing system integrity.

The TOC-750X

Our TOC 750X addressable Benzene gas detector is one of the most versatile detectors of its type on the market. With both display and non-display versions, the 750X offers a low ppm level of PID technology, perfect for ATEX applications. Our TOC-750S is our leading sampler benzene gas detector, offering stable and accurate detection of benzene gas through our piezo pump technology. Showcasing the industry first auto zero, this device will provide continuous accurate gas detection with an unparalleled zero stable for the sensor.

The TOC-750 Safe Area

Our TOC-750 safe area benzene gas detector is ideal for non-ATEX applications, providing cost-effective gas detection with the same reliability and accuracy as our ATEX solution. The 750 safe area benzene gas detector has multiple input and output options on the actual sensor. This means one detector can control up to 7 other devices including but not limited to: other gas detectors, slam switches, beacon sounders, gas supply valves etc. Thus, providing you with a versatile detector, reduced installation and cabling requirements and much needed distributed control without the need for expensive I/O cards.

Our Revolutionary new PID sensor

All of these fixed device’s feature IGDs revolutionary PID sensor. The unique electrode stack design for this benzene gas detector ensures the common issue of humidity is eradicated without affecting sensor performance. Our PID sensors also utilise a non-electrode UV lamp, dramatically extending the sensor run time by 200% compared to the market standard, providing a 30,000-hour runtime. This also negates another common issue of sputtering, giving clients the confidence that their sensor is performing at the highest level.

It is worth mentioning that almost all fixed benzene gas detectors are not benzene specific, so they will respond to any VOC. However, the NEO Benzene portable is benzene specific, thus will only respond to benzene. Therefore, IGD recommend the detectably better combined solution of implementing both the NEO benzene specific portable and a fixed benzene gas detector for benzene applications. The fixed device will act as a first responder, notifying the user that there is a VOC presence in the area. Then, the NEO benzene gas detector can be used for spot checking, giving an accurate reading, and letting you know whether or not it is benzene that is the hazard.

Contact IGD Today

IGD manufacture detectably better gas detection equipment, with a specialist team on hand to answer any questions straight from the manufacturer. To find out more about our range of benzene gas detectors, contact our team today or click here to visit the VOC and Benzene detection section of our website.